NEW!

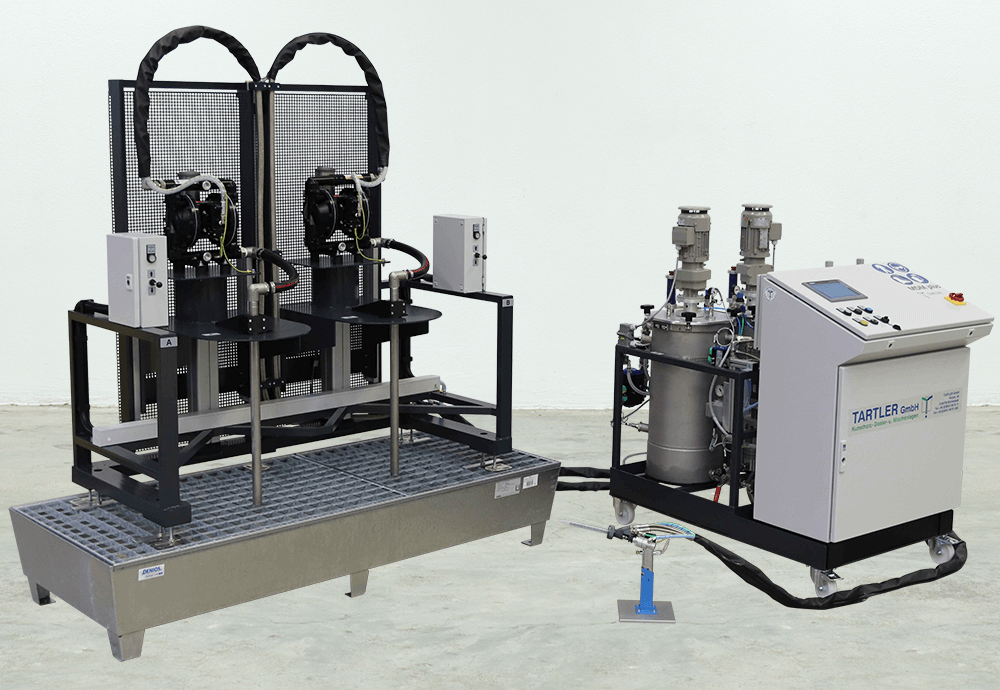

The new top model of the MDM series: The MDM plus fills the gap between the MDM 6 and the NODOPUR system. Despite its compact design, it has more technical equipment and a higher output of up to 6.5 l/min.

If you are looking for a compact dosing and mixing system for a maximum of 2 flowable components, you should take a closer look at the MDM series. With this range of systems, outputs of 0.05 l/min up to 6.5 l/min can be achieved.

Small quantities precisely metered

The MDM is characterized by high mixing ratio accuracy, ease of maintenance and the easy, functional operation via the Siemens LOGO control (from MDM 5) or a control via touch panel (Simatic S7) with the MDM plus.

The basic equipment includes plastic containers which are filled manually and are not pressurized with compressed air. Alternatively, the material can also be supplied via stainless steel containers or higher positioned containers. The dosing is done by means of high-precision gear pumps. Possible settings of the mixing ratio depend on the selected machine equipment.

Information about possible components and configurations can be obtained from our sales team.

Basic Equipment

- Suitable for liquid synthetic resins of polyurethane, epoxy and silicone

- Output ranges within 0.05 l/min to 6.5 l/min can be specified

- Adjustable mixing ratio (from MDM 4)

- Static mixer or disposable rotary plastic mixer (from MDM 4) possible

- Control: from simple user interface (MDM 3 / 4) to touch panel (MDM plus)

- Different tube lengths

- Stationary or mobile, powder-coated steel frame

Technical Data

| Components | 1 or 2 components |

| Viscosity range | 1 – 30,000 mPas |

| Mixing ratio | Fixed, manual, semi-automatic or software controlled |

| Flow rate | Can be specified in the range from 0.05 to 6.5 l/min |

| Control system |

|

| Container | Various container sizes from 0.6 l to 60 l available |

| Available options |

|

Module elements

A dosing system of the MDM series can be equipped with the following modules. As a manufacturer of special machines we adapt all machines to the respective process conditions.

- Quality-impairing air and humidity are removed from the resin

- Improved manufacturing process

- Enhanced product quality

Process-integrated evacuation of air and moisture from synthetic resins and hardeners before dosing and mixing with the T-EVAC degassing station.

With this module you can significantly improve your forming processes as well as your product quality. The new degassing station is suitable for both epoxy resin and polyurethane resin degassing.

The system solution is designed in two variants: First, as an offline degassing at a central location where several dosing units can be filled with degassed material. Second, as an inline degassing directly integrated into the dosing system and adapted to the process requirements.

Measurably better results with degassed material

Material test: Optimal result with degassed resin and hardener

Test result without degassing: visible air inclusions (light discoloration)

| Categories : |

Liquid components

|

|---|

All machine parts, from the container to the hose and mixing head, can be heated to reduce the viscosity of the material – for example, to shorten the pot life or improve mixing of the components. Depending on the application, there are several options available.

Container

- Jacket heating (adapted to the container)

- Double jacket (heating with water or oil)

- Extra agitators for a better heat distribution

Hoses

- Heated hoses

- Insulation

Depending on the sensitivity of the material, all possible cold spots must be additionally heated or insulated. Heating cartridges, ring heaters and heating tarpaulins are used in this process.

| Categories : |

Liquid components, Pasty components

|

|---|

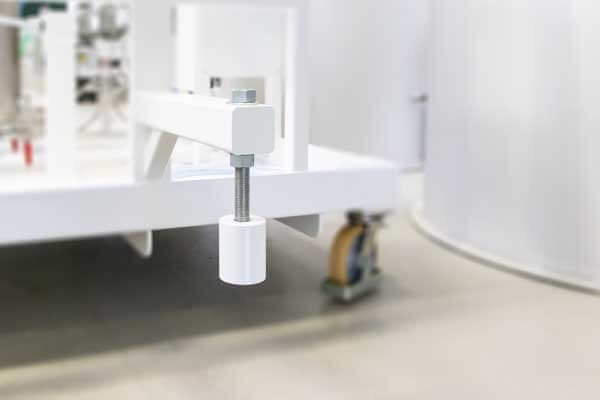

It may be necessary for a plant to be mobile, depending on its size and location/purpose. There are several ways to achieve mobility:

- Mobile frame

- Own drive unit

- Trailer coupling

| Categories : |

Liquid components, Pasty components

|

|---|

To keep the dosing process running longer, we offer refills from IBCs or drums. There are different solutions for the realization of a refill.

Automatic Refill

- 1st option: Dosing containers are connected to a mobile refilling station (modern connection with couplings without loss of material)

- 2nd option: Dosing containers are connected directly on the base frame with e.g. an IBC

- 3rd option: Refill containers are also located on the base frame

The process is controlled via automatic refilling e.g. when a minimum sensor level is reached.

Vacuum Refill

If the material must not come into contact with air, we offer dosing containers in vacuum atmosphere. When refilling, the negative pressure is used to “pull” the material out of the refill containers.

Free Refill

The free refill, also called “free-flow”, uses gravimetry. The material flows from the higher positioned refill container into the dosing containers. No pump is required.

| Categories : |

Liquid components, Pasty components

|

|---|

Sample projects / Already built systems

Data sheet

Download more information about the MDM series here.

We are happy to advise you!

We make consulting and service a top priority. If you are interested in or have any questions about the MDM series from TARTLER, please feel free to contact our experts at any time.

Markus Fesel

Technical Sales & Project Management

Phone: +49 (0)6061 9672-13

m.fesel@tartler.com

We are happy to advise you!

We make consulting and service a top priority. If you are interested in or have any questions about the MDM series from TARTLER, please feel free to contact our experts at any time.

Markus Fesel

Technical Sales & Project Management

Phone: +49 (0)6061 9672-13

m.fesel@tartler.com

News about small quantity metering with the MDM series

Always up-to-date with the TARTLER News!