NODOPUR 2K (0051)

Year of construction: 2013

Polyurethane casting machine suitable for easy processing of liquid crystal clear Axson EP resin:

- Translux D 154 resin (unfilled) = 3800 mPas, 1.16 kg/l (at RT), processing temperature = 20-25°C

- Translux D 154 hardener (unfilled) = 2200 mPas, 0.98 kg/l (at RT), processing temperature = 20-25°C

- Mixing ratio 100 : 84 parts by weight

- Mixing ratio 100 : 100 parts by volume

- Pot life : approx. 8 min.

- Material application on surface up to 2 x 4 m, approx. 4 mm thickness (approx. 24 -32 l)

Nodopur prepared for manual evacuation equipped with:

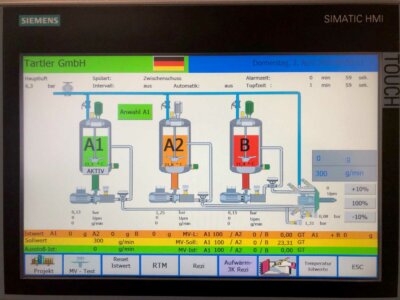

- Control: OP 77

- input signal for your robot -> start/stop – casting; shot quantity adjustable via robot

- ProfiNet

- tank A: suitable for vacuum, 30 l, heated (approx. 25-40°C), agitator (LZB33)

- Drive A: 3,0 kW (Lenze)

- Pump A: FPN 30,0 ccm

- Hose A: NW 12, 3.2 m, heated

- Tank B: suitable for vacuum, 30 ltr, heated (approx. 25-40°C), agitator (LZB33)

- Drive B: 3,0 kW

- pump B: FPN 20,0 ccm

- without gap filter

- Hose B: NW 12, approx. 3.15 m heated

- mixing head: LC 5/3, 1,1 kW EMOD

Additional:

- Vacuum pump rotary vane, 25 m³/h, 0,75 kW, final pressure < 0,5 mbar

Price: Matter of negotiation

Placement on customer’s behalf