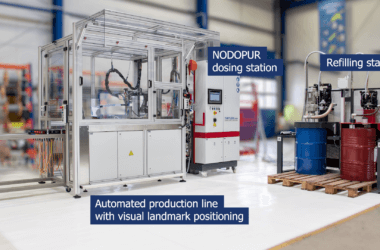

Innovative dosing, mixing and filling technology for synthetic resin application

Industry and customer solutions for highly efficient processing of liquid and pasty synthetic and reactive resins

Worldwide, TARTLER is regarded as a guarantor for state-of-the-art technology in the processing and application of low-viscosity and paste-like epoxy resins, polyurethanes and silicones.

TARTLER’s fully automated or manual single and multi-component systems are used in all key industries: In automotive and vehicle construction, in aerospace engineering, in wind power and energy technology, in model and mold making, in electrical engineering and microelectronics, in boat and shipbuilding and many other industries.