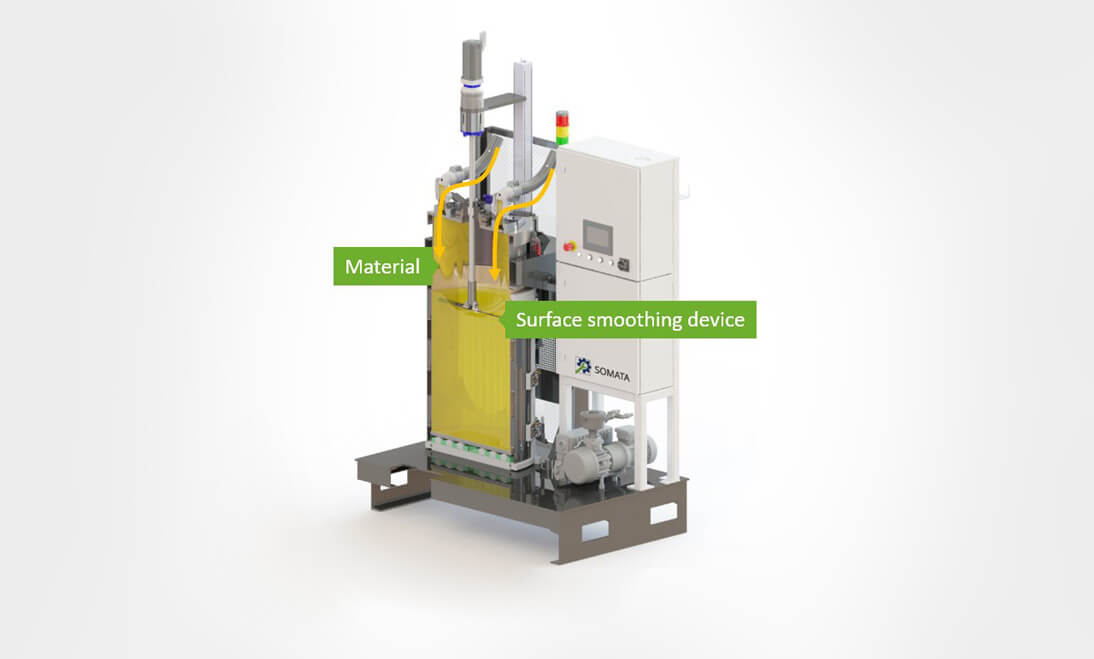

The vacuum filling station TAVA F is the forward-looking solution for cost-optimized and waste-free filling of flowable and pasty components used in synthetic resin processing. For all companies that work with metering and mixing systems and want to increase the quality of their synthetic resin applications, this degassing station clears the way for cost reduction and waste avoidance: As a resource-saving material preparation by degassing and eliminating air inclusions in the delivery container or as a preparation of unmixed residual quantities from ongoing production.

Are you interested in this machine from TARTLER? Then do not hesitate and contact us! We are at your disposal for further details and questions.

Benefits of the TAVA F filling station at a glance

- Material optimization before processing

- Reduction of material waste

- Process-oriented cost optimization

- Drum filling at the material manufacturer

Reasons for drum filling with TAVA F

- The material prepared in a vacuum drum is reliably freed from air inclusions and humidity. This means that only optimally prepared material enters the resin processing stage, causing no process disturbances and decisively improving the product quality!

- Unmixed material leftovers and residues can be processed in the TAVA F and fed back into the production process. This sustainably reduces waste volumes and lowers the cost of purchasing new material!

Tartler makes it possible: Already built plants

Basic Equipment

- Vacuum drum in stainless steel or steel (free choice of color)

- Clamping and fixing device

- Base with drum centering plate

- vacuum pump

- Control unit with touch screen

- Fill level monitoring

- Sight glass

- Hoses in different lengths

| Vacuum pump | 23-63 m³/h; ultimate pressure 0.1 mbar |

| Control system | Siemens SPS KTP700, Touch Screen |

| Container | 200 l drum (with and without inliner) |

| Compressed air connection | 6-8 bar |

| Power connection | 400 Volt |

- Vacuum drum with lid

- Connection for material supply

- Adjustable and self-regulating vacuum

- Sight glass

- Fill level monitoring

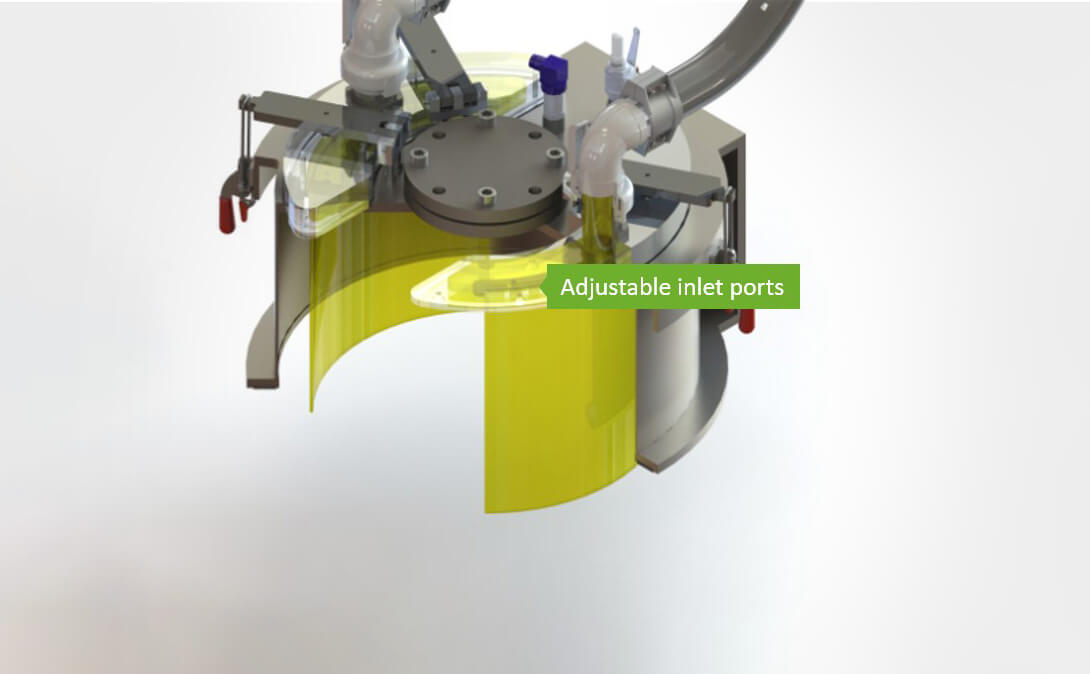

- Different inlet openings for material supply

- Pressure follower plate

- Adaptation to other container sizes

- Interchangeable filling nozzle for different product characteristics

- Multiple filling nozzles/product infeed

- Drum lifter or roller conveyor for drum handling

- Weighing system for accurate fill quantity determination

- Printer (reports/logging)

- Interchangeable machine parts (if different materials are to be degassed with one system)

- Filling lance (for filling from bottom to top with particularly highly viscous material -> no air voids between material layers)

- Smoothing brush for sealing the surface

- Ascending mixer plus smooth coater

- Data exchange with other filling systems (e.g. emergency stop signal)

- Various automation options

- Further special equipment possible

Versatile – the TAVA F can simply do more

TAVA F is not only a win for the resin processor! The material manufacturer also benefits from the use of the filling station. Thanks to filling using a vacuum pump, he can provide his customers with guaranteed process-safe containers without (moist) air inclusions. Since contamination of the material with air and humidity is ruled out, its storage stability is also improved.

The filling station for safe media handling without entrapped air

As an upstream system integrated into production, the TAVA F can significantly increase process reliability when the optimized material is subsequently processed in a metering, mixing and application system. The risk of process interruptions is minimized, as are all costs arising from material losses for rinsing and cleaning runs and for spare parts.

In combination with a pumping station for transferring – for example a NODOPOX 200 1K – all unmixed material residues that occur during drum changes or test runs for optimizing the mixing ratios can be reused. They can be collected and fed back into the processing after preparation in the TAVA F. This significantly reduces the costs for purchasing new material and for waste disposal!

Modules

For further process optimization in synthetic resin processing, the TAVA F degassing station can be adapted to individual requirements with the following modules.

- Other container sizes: Different container sizes can be filled with one TAVA F. Fast, tool-free container changeover; low cleaning effort for the product-carrying components.

- Handling technology: drum lifter, rope winch, roller conveyor, mobile base frames

- Weighing system for precise filling quantity determination

As a special machine builder, we can also implement many other process- or environment-specific adaptations in order to obtain a vacuum filling station tailored exactly to your requirements.

The alternative for low-viscosity components

For air- and moisture-free filling and transfer of very liquid and low-viscosity components into the tanks of dosing and mixing systems, into buffer tanks or into IBCs, we also recommend our T-EVAC degassing system. It is available to you in the inline and an offline variant.

Inliner squeezing device

- This device helps you squeeze out the material left in the inliner almost completely and in a controlled manner, without any risk to the user’s safety

Art. No. V-ALL 0131

These options are available for the TAVA F filling station

Choice of inlet port (adjustable and replaceable) depends on material/viscosity

- Goal: create a material surface as large as possible for optimum vacuum degassing

| Categories : |

TAVA F modules

|

|---|

Clean, smooth and reproducible surface for non-self-leveling materials

- Goal: sealing the surface

| Categories : |

TAVA F modules

|

|---|

Stirring the material during the filling process prevents possible bubble formation. After filling, the surface is smoothed out.

- Goal: No air pockets and sealing the material surface

| Categories : |

TAVA F modules

|

|---|

For filling “from the bottom up” of very pasty components that have been mixed under vacuum.

- Goal: During filling, no layers of material are created between which air could be trapped

| Categories : |

TAVA F modules

|

|---|

Dosing of collected, unmixed material residues into the TAVA F and processing without air or bubbles.

- Goal: provide opened drums and material residues in completely filled drums for production; waste reduction; process safety

| Categories : |

TAVA F modules

|

|---|

Data sheet Vacuum Filling Station TAVA F

Download here the information about the vacuum filling station TAVA F free of charge.

Download Inquiry Form (PDF)

Inquire about your TAVA F filling station today. Either online with a few clicks or download the inquiry form as an interactive PDF here.

We are happy to advise you!

Consulting and service are of key importance to us. If you are interested in the TAVA F vacuum filling station and all other Tartler machines, please contact our experts at any time.

Markus Fesel

Technischer Vertrieb & Projektmanagement

Phone: +49 (0)6061 9672-13

m.fesel@tartler.com

We are happy to advise you!

Consulting and service are of key importance to us. If you are interested in the TAVA F vacuum filling station and all other Tartler machines, please contact our experts at any time.

Markus Fesel

Technischer Vertrieb & Projektmanagement

Phone: +49 (0)6061 9672-13

m.fesel@tartler.com

News about the vacuum drum

Always up-to-date with the TARTLER News!