TARTLER GROUP implements an integrated system solution for cutting-edge encapsulation technology

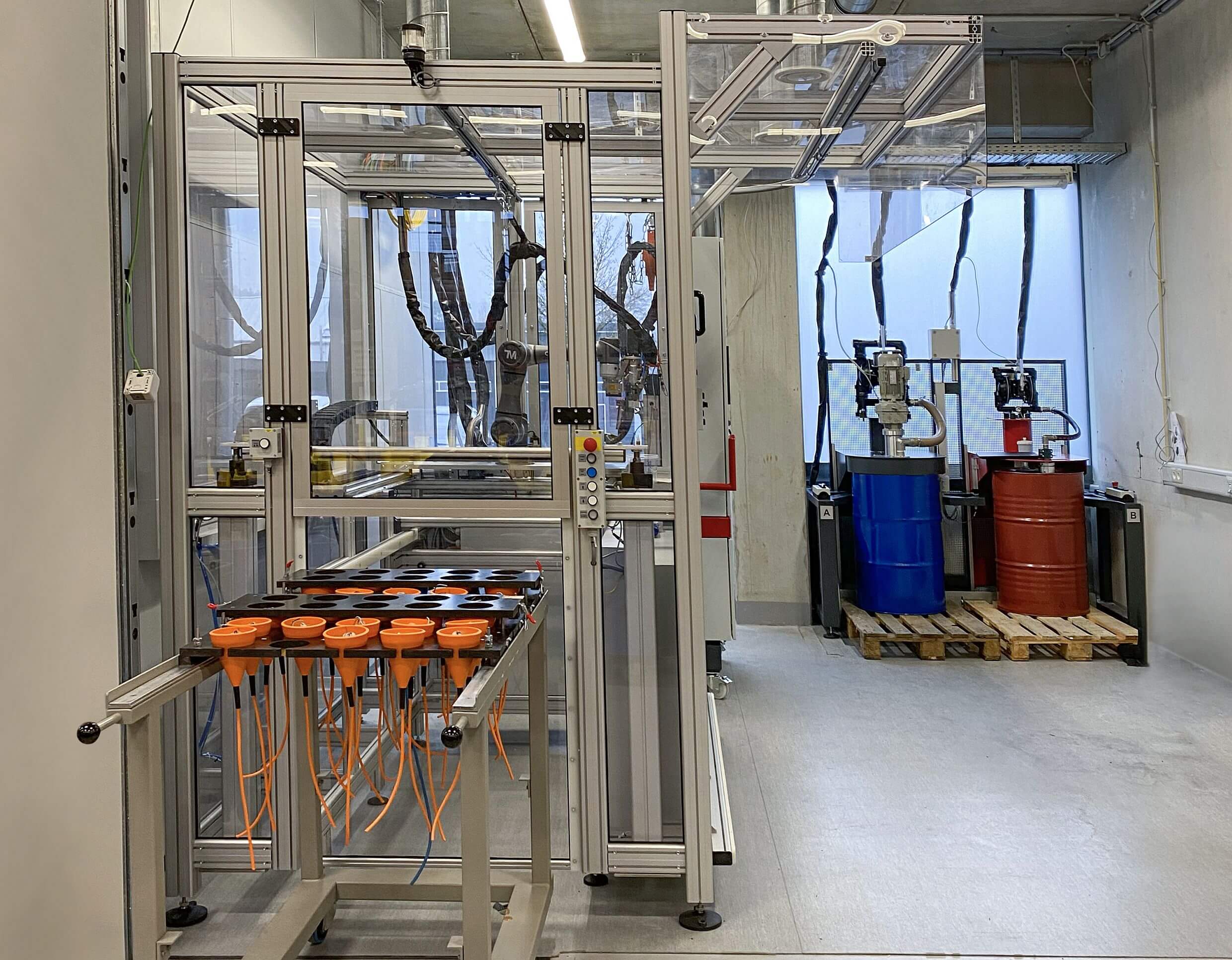

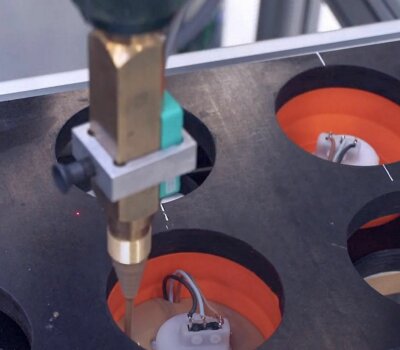

For increased productivity and efficient production of large quantities, more and more electrical engineering companies are taking advantage of the possibilities offered by automated encapsulation. In order to serve these needs, the TARTLER GROUP has developed a complete solution consisting of a resin dosing and mixing system, a robot-assisted encapsulation station and an external refilling unit for a renowned manufacturer of plug connector and motor protection products.

Michelstadt, April 2023. – Regardless of the quantities involved, grouting is a traditional encapsulation process used in the production of electrical and electronic components and assemblies. Circuit boards, transformers, controllers or sensors, for example, are coated with a synthetic resin coating or encased in a block of synthetic resin that offers electrothermal insulation and protection against splash water, dust and humidity. Two-component systems of polyurethane, epoxy resin or silicone are usually used for this purpose, which have to be processed according to defined parameters. Dosing and mixing are just as important as application and pouring of the free-flowing compounds. These requirements are fully covered by the portfolio of Tartler Group, a leading medium-sized plant manufacturer based in Germany. When the group recently received an order from a well-known manufacturer of motor contactors and plug connectors to implement a fully automatic electric encapsulation station, a decisive factor for the award was the finely balanced interaction between the parent company – TARTLER GmbH – and its subsidiaries. The result was a modern complete solution consisting of a flexibly controllable dosing and mixing system, a robot-assisted application system and a 2K refill unit that enables continuous encapsulation of already wired assemblies.

Michelstadt, April 2023. – Regardless of the quantities involved, grouting is a traditional encapsulation process used in the production of electrical and electronic components and assemblies. Circuit boards, transformers, controllers or sensors, for example, are coated with a synthetic resin coating or encased in a block of synthetic resin that offers electrothermal insulation and protection against splash water, dust and humidity. Two-component systems of polyurethane, epoxy resin or silicone are usually used for this purpose, which have to be processed according to defined parameters. Dosing and mixing are just as important as application and pouring of the free-flowing compounds. These requirements are fully covered by the portfolio of Tartler Group, a leading medium-sized plant manufacturer based in Germany. When the group recently received an order from a well-known manufacturer of motor contactors and plug connectors to implement a fully automatic electric encapsulation station, a decisive factor for the award was the finely balanced interaction between the parent company – TARTLER GmbH – and its subsidiaries. The result was a modern complete solution consisting of a flexibly controllable dosing and mixing system, a robot-assisted application system and a 2K refill unit that enables continuous encapsulation of already wired assemblies.

Michelstadt, April 2023. – Regardless of the quantities involved, grouting is a traditional encapsulation process used in the production of electrical and electronic components and assemblies. Circuit boards, transformers, controllers or sensors, for example, are coated with a synthetic resin coating or encased in a block of synthetic resin that offers electrothermal insulation and protection against splash water, dust and humidity. Two-component systems of polyurethane, epoxy resin or silicone are usually used for this purpose, which have to be processed according to defined parameters. Dosing and mixing are just as important as application and pouring of the free-flowing compounds. These requirements are fully covered by the portfolio of Tartler Group, a leading medium-sized plant manufacturer based in Germany. When the group recently received an order from a well-known manufacturer of motor contactors and plug connectors to implement a fully automatic electric encapsulation station, a decisive factor for the award was the finely balanced interaction between the parent company – TARTLER GmbH – and its subsidiaries. The result was a modern complete solution consisting of a flexibly controllable dosing and mixing system, a robot-assisted application system and a 2K refill unit that enables continuous encapsulation of already wired assemblies.

Michelstadt, April 2023. – Regardless of the quantities involved, grouting is a traditional encapsulation process used in the production of electrical and electronic components and assemblies. Circuit boards, transformers, controllers or sensors, for example, are coated with a synthetic resin coating or encased in a block of synthetic resin that offers electrothermal insulation and protection against splash water, dust and humidity. Two-component systems of polyurethane, epoxy resin or silicone are usually used for this purpose, which have to be processed according to defined parameters. Dosing and mixing are just as important as application and pouring of the free-flowing compounds. These requirements are fully covered by the portfolio of Tartler Group, a leading medium-sized plant manufacturer based in Germany. When the group recently received an order from a well-known manufacturer of motor contactors and plug connectors to implement a fully automatic electric encapsulation station, a decisive factor for the award was the finely balanced interaction between the parent company – TARTLER GmbH – and its subsidiaries. The result was a modern complete solution consisting of a flexibly controllable dosing and mixing system, a robot-assisted application system and a 2K refill unit that enables continuous encapsulation of already wired assemblies.

The resin mass produced in the

The resin mass produced in the