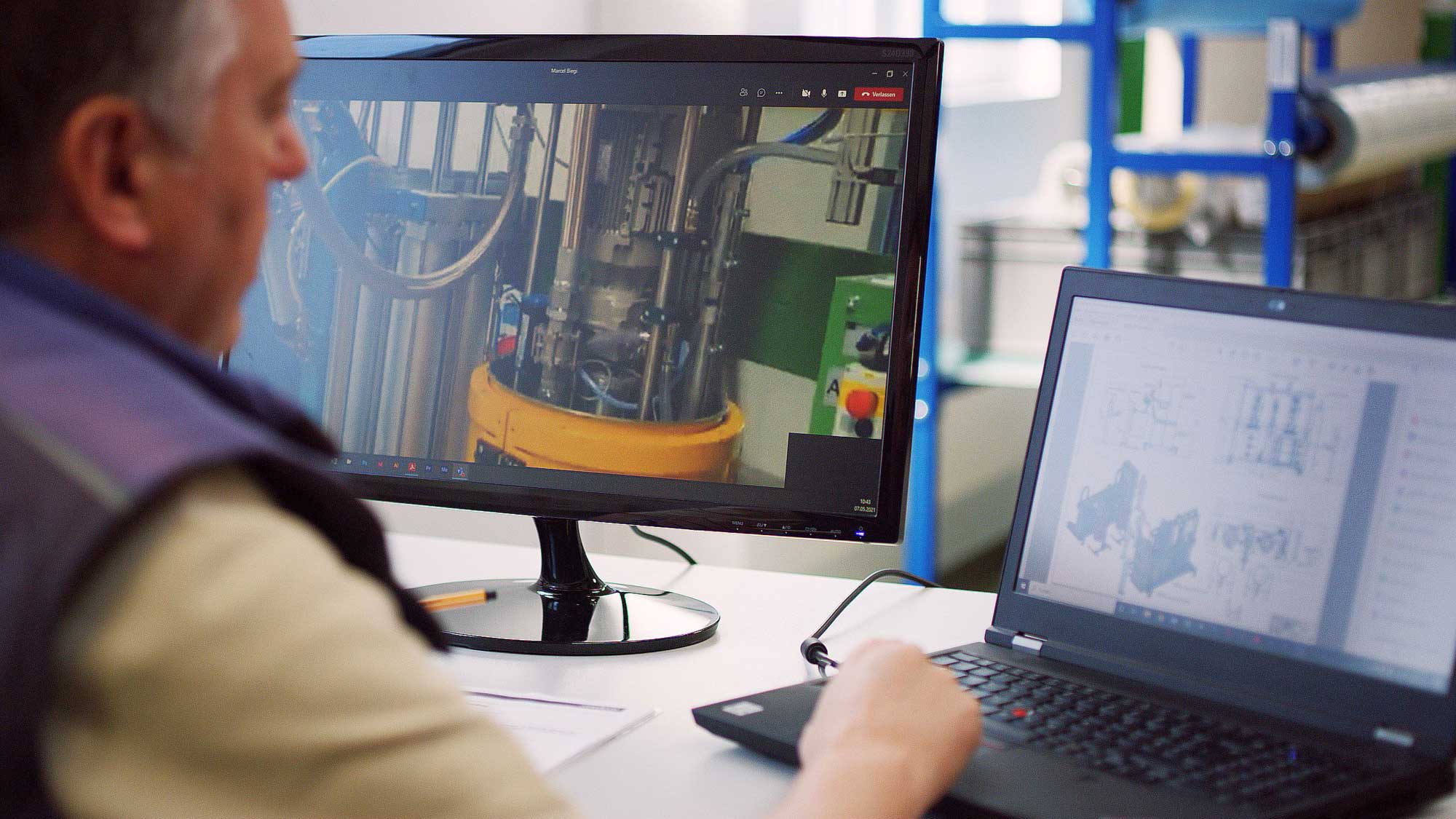

TARTLER GmbH: A performance worthy of a film | Imagefilm 2021

9. August 2021

Join our journey and find out more about what TARLTER does! In what kind of industries are the machines used [...]

Tags: Company, Product portfolio, TARTLER GROUP, Team

24. June 2022

Udo Tartler “Thanks to our engineering competencies and our injection molding production, we can always realize disposable mixers for process-related borderline cases or individual customer requirements beyond the standard range.”

TARTLER’s vast range of mixers for modern resin systems is currently unrivaled in the industry. In line with its guiding principle “Mixing is possible”, the German plant manufacturer’s in-house injection molding lines produce the optimal disposable mixer for almost every scenario of single- and multi-component processing. Even the standard range offers a large number of immediately available variants for high-viscosity, filled, low-viscosity or liquid materials. Since they are made of single-grade POM and also minimize the use of environmentally harmful rinsing agents during mixing head cleaning, they prove to be a highly sustainable solution in practice.

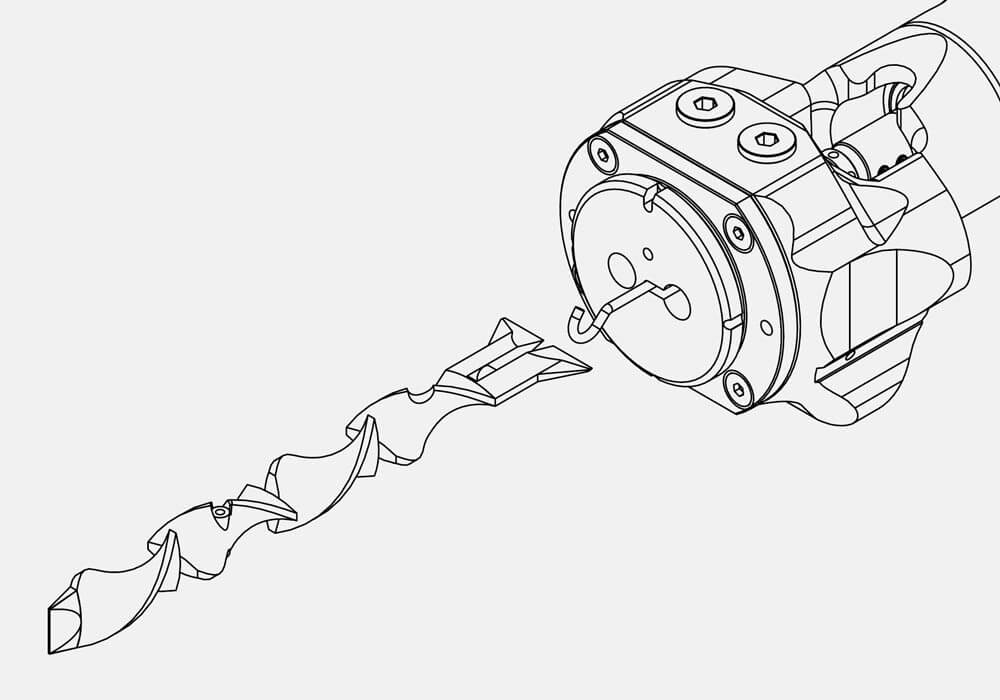

No task in synthetic resin technology is impossible for TARTLER’s dosing and mixing technology specialists. This is evident not only from the plant manufacturer’s current range of machines and equipment, but also from the impressive selection of mixing heads that the German company provides to polyurethane, epoxy resin and silicone processors. But that’s not all: As a technological pioneer in the field of dynamic resin mixing, TARTLER has for many years focused strongly on the development and production of innovative and highly efficient disposable mixers. As a result, the company can now supply a customized mixer variant for almost every case of single- and multi-component processing: Ready for use in the right size, with the optimum spiral geometry, the most suitable connection as well as equipped with additional functions and supplemented with a matching sleeve. Whether high-viscosity, paste-like, filled, low-viscosity, liquid, warm or hot materials are to be processed in small or large quantities, TARTLER covers almost all facets of modern resin systems – even with its standard selection of disposable mixers. “In addition, based on our engineering expertise and our injection molding production, we can implement mixers for borderline process engineering cases, new requirements or individual customer requirements at any time,” says CEO Udo Tartler.

Basically, TARTLER’s current mixer range is divided into three main groups. The largest group is disposable mixers, which can be attached onto the drive hook of the mixing head and enable dynamic mixing through the rotation set in motion from here. This principle, in which the material is mixed quickly and very homogeneously by the rotating mixing spiral immediately before ejection, is considered a TARTLER invention and has set the standard in synthetic resin processing for over three decades. The company manufactures the mixers designed for this purpose in numerous widths and lengths with various spiral geometries with 4, 6, 8, 12 or 24 mixing segments. Furthermore, variants with additional functional components are available: With scraper for materials that tend to form agglomerate, with cone for quick closure of the mixer outlet after each end of the shot or with integrated pulse generator for speed monitoring. This list also includes special variants for processing materials with temperatures of up to 200° C as well as special versions for combination with TARTLER’s LC 6 and LC7 mixing heads. “These mixing heads are characterized in particular by their compact and easy-to-maintain design,” explains Udo Tartler.

The second group is made up of disposable mixers for use with mixing heads that have the innovative self-tapping connections. The mixing spiral does not have to be attached to a hook here, but turns itself onto a threaded mandrel. The mandrel forms the mechanical interface to the mixing head drive and also enables dynamic mixing. The disposable mixers of this type are available in the same diameters and spiral geometries as the hook solutions and are also available with pulse generators for speed monitoring. The decisive advantages of the self-tapping mixer connection are increased process reliability and fully automatic mixer change if desired.

Finally, the third group includes a range of disposable mixers for static mixing. Here, the user can choose between different sized variants with 18, 23, 24 and 32 mixing segments and use as many mixers as required – for example as a hose mixer. Suitable for all mixer types, TARTLER supplies the obligatory sleeves, which can have additional different functional elements. For example, there are sleeves with a grommet for connection to a hose, with an aluminum adapter to increase the back pressure, or with a slip-over burst tube to improve work safety.

The user can get an initial overview of which disposable mixer is best suited to which mixing heads and for which requirements on the TARTLER website (www.tartler.com). The company’s competent contact persons are then available for all detailed questions. From them, the customer will also learn that the use of disposable mixers reduces to an absolute minimum the consumption of environmentally harmful cleaning agents for rinsing the mixing heads, since the mixing of the material takes place in the disposable mixer itself, immediately before the material is discharged. If powered disposable mixers (keyword: dynamic mixing) are used, the user additionally benefits from better mixing results without mixing errors at the start of application. “In addition, the variable speed control enables optimum mixing results, even for special materials with very different properties,” says Udo Tartler.

In many places, changing disposable mixers is still a nuisance, as the mixing helix (mixing spiral) must be attached to the rotary-driven connection flange of the mixing head via an eyelet with a hook. However, this stands in the way of further automation in synthetic resin processing. TARTLER therefore developed a driven mixer connection with a self-tapping thread, whose conical threaded mandrel presses itself into the mixing helix, provided with a suitable bore, within seconds. Without manual intervention, this “self-assembly” creates a precisely fitting, friction-locked connection between the mixing helix and the connecting flange, which closes more tightly with increasing torque. No manual intervention is required for disassembly, as the complete mixer (helix and sleeve) is blown off directly after curing with the reverse gear of the mixer drive. In combination with the rotating disposable mixing spirals, this opens up a lot of potential for process automation in the low-pressure range.