Clear View Through the Glasses

28. May 2021

Plant Manufacturer TARTLER Expands Its Range of Customer-oriented Web Services TARTLER dosing, mixing and degassing systems are used worldwide in [...]

30. July 2021

The modular dosing, mixing and filling systems of TARTLER GmbH are considered to be highly innovative and are used today in all important branches of industry worldwide. Wherever synthetic resins are produced and processed, the machines, modules and systems of the German plant manufacturer are at the heart of the action. In a new company video, TARTLER now bears witness to the high standard of quality it achieves and the consistency with which it implements the process engineering requirements of its customers.

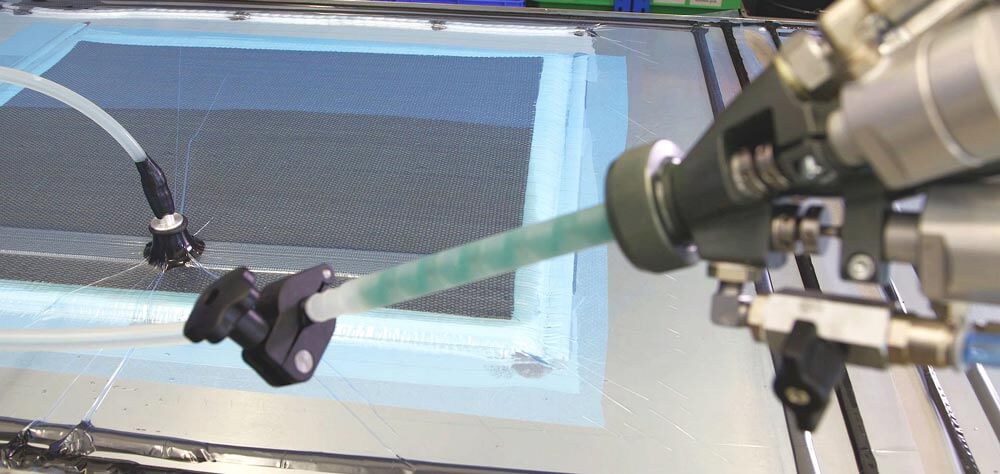

High-quality synthetic resin mixing heads for dynamic multi-component processing, modular dosing, mixing and degassing systems for safe material handling, revolutionary system solutions for clay processing, and high-precision dispensing mixers for minimum quantity applications – these are just some of the many innovations with which TARTLER has optimized and modernized its customers’ processes in recent months. The equipment and systems of the German company are regarded as guarantors of material quality, process efficiency and precision. They are used in aerospace, automotive and electrical engineering, in model and mold making or in the furniture, construction and wind power industries – wherever liquid and paste-like synthetic resins are produced and applied. To give its growing customer base a concise and informative overview of its highly diverse portfolio, TARTLER has produced a new company video that highlights all facets of its current range of machines, equipment and services, and can be viewed on the company’s YouTube channel. Especially for designers, product developers and process optimizers who use polyurethanes, silicones and epoxy resins for molding as well as adhesives, sealants or potting compounds, the new TARTLER video offers highly interesting insights into the thinking and working methods of the medium-sized plant manufacturer.

In less than four minutes, the new TARTLER video introduces viewers to all of the company’s key business areas, so that they can experience its comprehensive understanding of customer orientation, the wide range of services it now covers and the international markets where it is present. How do you handle challenging mix ratios and large viscosity differences? How do you support customers in the installation of complex production systems? What possibilities are offered by CAD design and the in-house research, development and demonstration center R.D.D.? And what solutions does TARTLER offer in view of the constantly increasing quality demands in synthetic resin processing? The new company video answers all these questions in words and pictures. The video also addresses the company’s intensive cooperation with renowned material manufacturers as well as its emergency service, online remote maintenance and spare parts logistics.

Product Lifecycle Management (PLM), quality and internationalization are topics that run as a thread through the new TARTLER video. For example, viewers are introduced to the company’s comprehensive service concept, which ranges from initial consultation through all phases of development and production to commissioning and user training, thus covering the entire product life cycle of the systems and machines. What’s more, they can learn about TARTLER’s vertical range of manufacture and the high quality standards that are consistently implemented. And last but not least, the video gives viewers a backstage look into current developments of the TARTLER GROUP and its subsidiaries in Germany and Asia.

Pleasant to watch: TARTLER’s new corporate video deliberately does without flashy effects, bombastic slogans or a dramatic musical background. Instead, it is designed to provide information and transparency, enabling designers, product developers and process optimizers to obtain clear information on how they can use the company and its services to accomplish their tasks in synthetic resin processing.