A Cornucopia of Innovative Solutions

9. September 2020

If you want to apply liquid synthetic resins in thin layers in web form, you will find special flat nozzles [...]

19. February 2021

Around the globe, TARTLER’s dosing, mixing and degassing systems contribute to the efficient production of modern wind turbine rotor blades. They are used in all relevant process stages: from the construction of molds to the production of half-shells and their bonding to the finishing of blade surfaces. They support automation, ensure optimum use of materials and increase safety when handling synthetic resins. Read here which TARTLER plants and system solutions are primarily used in the wind power industry today.

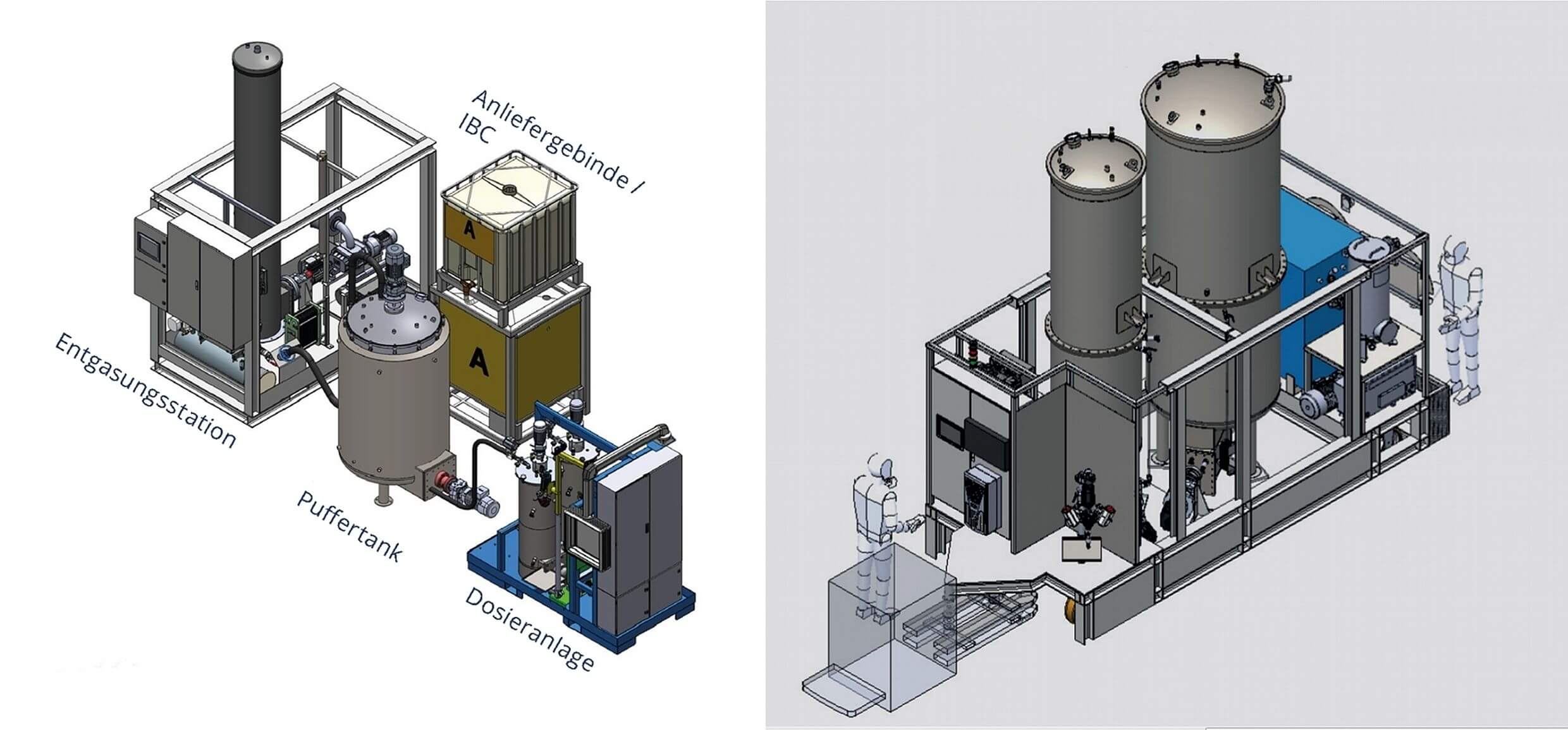

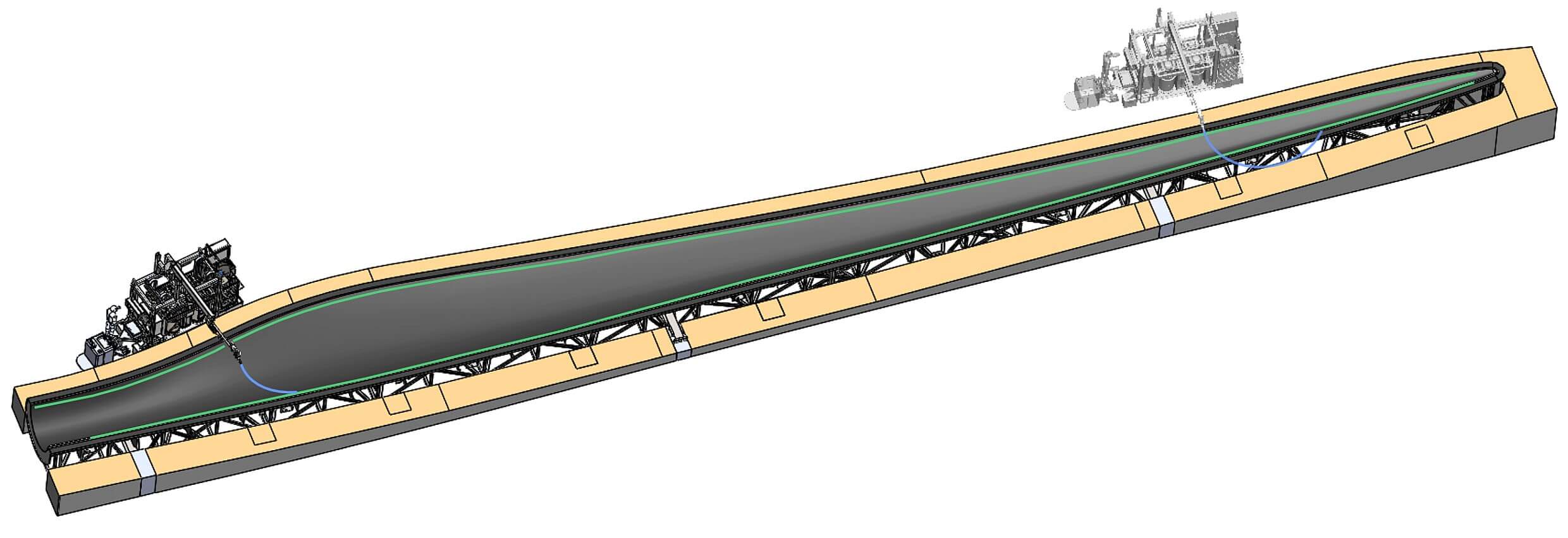

Modified polyurethanes, epoxy resins and flexible glass fiber products are key materials in the design and production of modern wind power rotor blades for onshore and offshore turbines worldwide. They are not only used for the application of tooling pastes and EP resins during the construction of large molds and models, as well as for the production of the two blade half-shells and their bonding, but also for the application of weatherproof surface layers as well as leveling compounds and numerous finishing operations. Numerous well-known manufacturers in the wind energy sector, such as TPI or Vestas. rely on the modular system solutions of the German plant manufacturer TARTLER to carry out these tasks. Not only the dosing and mixing machines of the Nodopur, Nodopox and Tardosil series can now be found in numerous rotor blade manufacturing plants, the innovative T-EVAC degassing station for infusion resins and TARTLER’s vacuum barrel changer, for which a patent has now been filed, are also enjoying increasing demand. Thanks to the reprocessing of pure residual quantities, a significant reduction in waste can be achieved. “Often, our solutions enable manufacturers to implement key process optimization and automation measures. In addition, they support the loss-free use of materials and increase safety standards when transferring the synthetic resin components from the material suppliers’ containers,” says company boss Udo Tartler.

Company boss Udo Tartler: “With our dosing and mixing equipment and vacuum degassing stations, we enable rotor blade manufacturers to implement important process optimization and automation measures.”

Many rotor blade producers apply the gel coatings to the inner surfaces of the cavities using TARTLER’s Nodopur or Tardosil 2-component dosing and mixing systems. With these systems, the primers of silica and thickened synthetic resins, which primarily serve to mechanically protect the surfaces and seal them against moisture, can be applied very homogeneously and quickly. This is ensured, among other things, by integrated volume flow controls with which mixing ratios and output quantities can be automatically adjusted. Both systems are controlled by PLC from Siemens, are suitable for different dosing ratios and can be operated with different mixing heads from the TARTLER range. As their name suggests, the Nodopur machines are predestined for processing polyurethane and epoxy resins, while the Tardosil machines are also designed for silicones. “Both series are also used when precisely metered leveling compounds are introduced into the rotor blades for balancing,” adds Udo Tartler.

For vacuum direct infusion – the patent-pending method for turbine blade production developed by TARTLER – the two-component dosing and mixing system Nodopur is used widely used. It can eject up to 30 liters per minute, has an automatic vacuum refill unit and a Siemens PLC with touch screen. TARTLER offers a variety of different mixing heads for this plant variant as well as the option of equipping it with a swiveling boom to optimize handling. In addition, this infusion system – like many other machines from the company – can be combined with the T-EVAC vacuum degassing station. “This station is used for the process-integrated and safe evacuation of air and moisture from the synthetic resins and hardeners, prior to dosing and mixing,” emphasizes Udo Tartler.

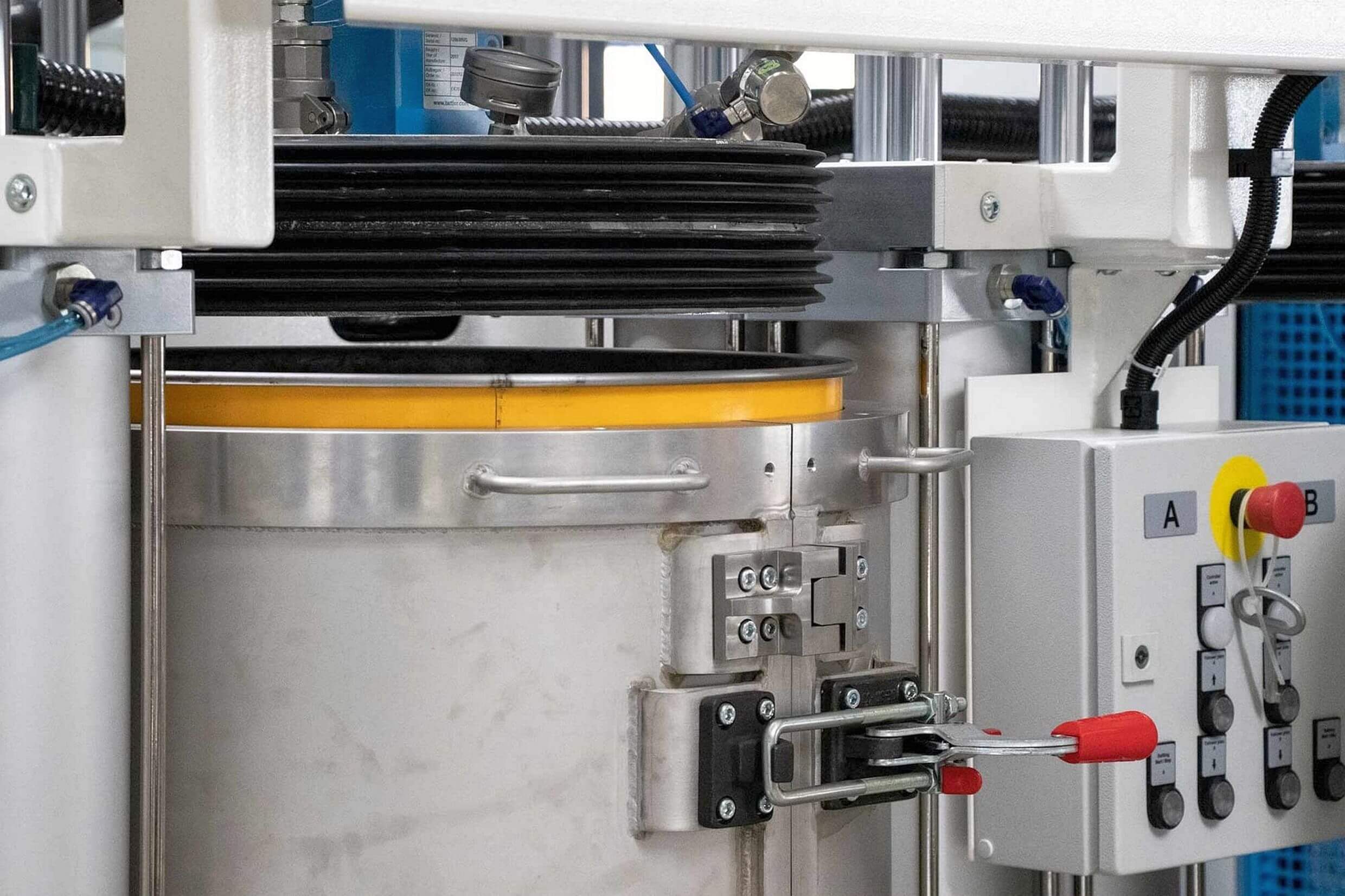

After both blade half-shells have been shaped by vacuum infusion, they are glued together to form the finished rotor blade. For years, the TARTLER systems of the established Nodopox series, designed for the processing and application of highly viscous, paste-like plastics, have been widely used in the industry. For some time now, new standards have been set here by a Nodopox variant equipped with the integrated vacuum-assisted drum changing system TAVA D for waste reduction and a swiveling mixing head boom with a 5-metre radius (optional). This plant is also equipped with a Siemens PLC with touch screen and a volume flow control. It can work with different TARTLER mixing heads and dispenses up to 20 kilograms of adhesive per minute.

Another typical TARTLER “gluing system” is the Nodopox, whose equipment is adapted to so-called lightning and insert applications in rotor blade production. Udo Tartler explains: “Adhesives are used that have to be metered, mixed and applied in smaller quantities – for example, for fastening lightning conductors or inserting inserts for screw mounting complete blades. These systems are operated both manually and in combination with robots and handling units. Finally, when it comes to filling and smoothing the adhesive edges, it is once again the Tardosil mentioned above that allows the putty used for this purpose to be precisely and quickly dosed, mixed and applied. In this case, too, TARTLER offers its customers numerous options for application-specific adaptation. The large assortment of modules offers a lot of freedom for optimal, application-specific customization of the systems.

Since TARTLER is able to adapt all systems very precisely to the specific requirements and on-site situation of the customer, they fit seamlessly into the customer’s production environment as tailor-made system solutions. They are often an important performance factor in the increasingly automated processes of modern rotor blade production lines. “Since we provide manufacturers with several innovative interface solutions at the same time with our vacuum-assisted drum changing system TAVA D and the vacuum filling station TAVA F as well as the liquid resin evacuation system T-EVAC in the offline and inline variants, we open up many additional possibilities for process optimization and increased efficiency in the processing and application of synthetic resins,” says Udo Tartler.