“In particular, resin users and composites processors who are dissatisfied with current vacuum infusion methods due to safety-critical material accumulation, poor material degassing and high installation costs are cordially invited to visit us at JEC 2022 in Paris. This is where we will be presenting the new TARTLER direct infusion to an international audience for the first time,” says Managing Director Udo Tartler with a view to the forthcoming market launch. As things stand, the new system solution is an innovative alternative to the previously used – and often suboptimal – variants of vacuum infusion. Both initial customer projects and benchmarks in the company’s own research and development center (F.E.D.) show that TARTLER’s direct infusion technology can boast numerous process and safety advantages. This includes, for example, the fact that it achieves a high degree of repeatability thanks to precise real-time control of the infused resin quantities, the proportional material weights and the mixing ratios. Another advantage is that the system allows the use of faster hardeners without the risks of unwelcome resin build-up with its tendency to exothermic reaction, and that its precise temperature control enables very short infusion times – which in composite systems ensures rapid impregnation of the fiber fabrics and thus reduces process times. “For all this, we neither need containers with already mixed resin masses nor elaborate installations with complex sensor technology. Instead, the linchpin of the TARTLER direct infusion system is an intelligent pressure regulation system. It ensures that the optimum application pressure is always applied at the inlet of the mold – which results in numerous process advantages,” reports Olav Davis, TARTLER’s Head of Research and Development.

Research & developement manager Olav Davis: “The decisive aspect of TARTLER direct infusion is the intelligent pressure regulation. It ensures that the optimum application pressure is always present at the mold inlet – which results in many process advantages.”

Always optimal infusion pressure

The new TARTLER solution is therefore a pressure-controlled direct infusion system in which all pressure fluctuations caused by operation are automatically compensated. This applies to all system-typical influences – even those resulting from the different pressure resistances of different hose lengths or mold height differences. This allows rapid, safe and material-optimized resin delivery to the mold inlet, ensuring that the full vacuum pressure is always present in the mold. As a result, TARTLER direct infusion opens up many new approaches to process optimization for the user. For example, it can reduce the curing time through the use of faster hardeners and, thanks to intelligent control of the pressure compensating system, it can dose at a significantly higher flow rate – with the same infusion set-up. What’s more, according to Olav Davis, “Thanks to the continuous permanent supply of fresh material, the system requires a lower volume flow on average than a bag-based infusion system or a standard infusion system, which always rely on the rapid supply of a lot of material.” Incidentally: No residual quantities of premixed resin masses from process bags or buckets arise for disposal.

Closed and mobile system

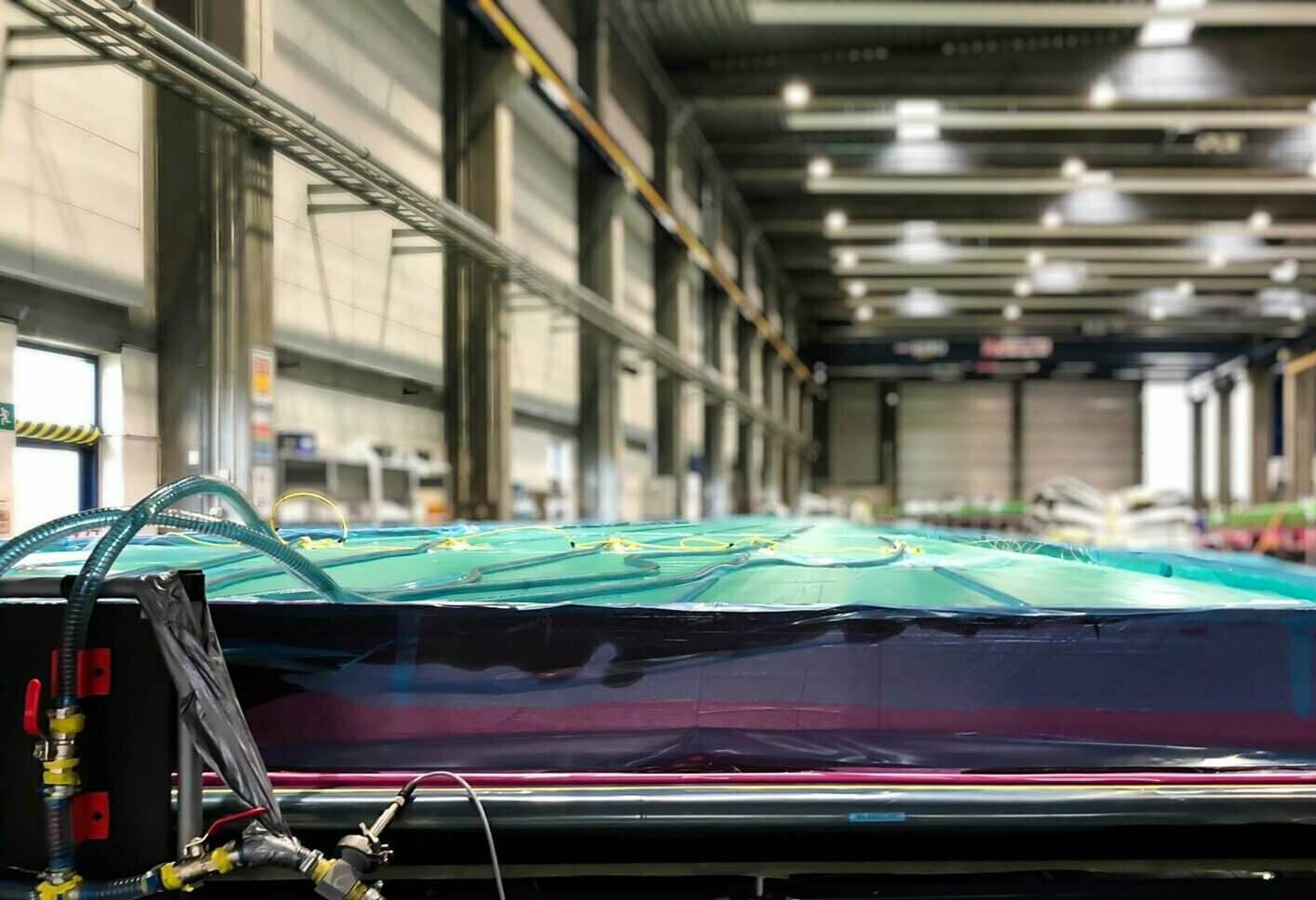

TARTLER’s new solution for pressure-compensated vacuum infusion comes as a fully equipped Nodopur dosing, mixing and application machine. With its tanks, pumps, pipes and mixing head, the touch-screen operated plant forms a closed system that does not allow air or moisture to penetrate the resin. The fact that – as indicated – it does not require external pressure sensors, load cells or resin tanks that need to be monitored simplifies operation considerably and reduces both running costs and the effort required for installation, maintenance and monitoring. In addition, the system is mobile, making the installation of inflexible installations obsolete. One or more Nodopur VS AR VF Infusion systems can be adapted to changing production conditions in boat building, car body construction or in the production of rotor blades for wind power technology in just a few steps.

Sustainable and economical

With the TARTLER direct infusion method, the user receives a whole bundle of advantages. The process is not only safe and efficient, but is also proven to be material-saving and cost-cutting, thus optimizing vacuum infusion from the ground up. By using a vacuum degassing station from its T-EVAC series, TARTLER opens up the next higher level of optimization for fiber composite technicians, thanks to low material waste as well as improved infusion and resin quality. These stations are placed upstream of the direct infusion system: As an offline central unit to supply several dosing/mixing units or as an inline system directly integrated into a Nodopur. Before the actual processing, they free the epoxy or PU resins from air and moisture in a hermetically sealed vacuum process and bring them to the desired application temperature. This means that only optimally conditioned material enters the infusion process, which has excellent properties for impregnating the fiber fabrics and does not cause any process disturbances.

The offline T-EVAC is available in two variants: For direct connection to the dosing/mixing system or with an additional buffer tank, which considerably reduces refilling times. In the process, this tank is located between the degassing station and the Nodopur VS AR VF infusion. “It is used for safe temperature-controlled storage of the degassed material under full vacuum and rapid filling of the dosing systems,” says Olav Davis. With the inline solution, the T-EVAC becomes a component of the dosing/mixing system. Thus, filling and material degassing take place in one step, whereby the machine can be filled synchronously with the application. The inline T-EVAC requires less manpower and floor space. When operated with only one dosing/mixing system, it is also more cost-effective than the offline variant.

Trendsetting combination

With its new direct infusion process and the evacuation stations of the T-EVAC line, TARTLER offers an innovative, forward-looking and complete process solution for many vacuum infusion technology applications. Composites industry professionals are welcome to take a closer look at this top-notch solution at JEC 2022 in Paris-Nord Villepinte. TARTLER can be found here at the joint stand for Hessen.