Liquid components

Pasty components

Liquid + pasty components

Vacuum technology

Accessories

Overview of Dosing Systems and Products

The right system for every application: as a manufacturer of special machines, we combine the right modules from our portfolio for every process. In this way we can respond to your individual requirements and finally deliver the optimal solution in the highest quality.

With our dosing systems you can process polyurethanes, epoxy resins and silicones with proven low-pressure technology.

Machine selection is primarily based on the viscosity of the materials at processing temperature.

The special thing about TARTLER: We manufacture the required switch cabinets, mixing heads and attachments within the group. The mixers and other injection molded parts are also manufactured by our long-standing partner in our own molds. The control units are also programmed in-house. This allows us to achieve perfect interaction – optimally matched to the components used – and at the same time make a difference to the environment and your wallet. The use of our patented disposable mixer means that no environmentally harmful cleaning or rinsing agents are required and the mixer does not have to be disposed of in hazardous waste when hardened.

We are particularly proud that we are able to master time and again new, challenging processes with extreme mixing ratios or large differences in viscosity. As our motto goes “Mixing is possible!”

We are happy to advise you!

Consultation and service are very important to us. If you are interested and have any questions about TARTLER machines and accessories, please feel free to contact our experts at any time.

We are happy to advise you!

Consultation and service are very important to us. If you are interested and have any questions about TARTLER machines and accessories, please feel free to contact our experts at any time.

Dosing and Mixing Systems

Processing of Liquid Plastics

Discover our dosing and mixing systems for liquid components made of polyurethane, epoxy resin or silicone. When selecting the machine components, the focus is always on the goal of a pulsation-free dosing process and maintaining the mixing ratio.

“Liquid components” are materials with a viscosity of up to max. 60,000 mPas, thus including “highly viscous liquids” which can be described as flowable or self-leveling.

Dosing Mixing Head LV 2/2

- Smallest quantity dosing for fluid components

- Shot quantities adjustable from 1.0 to 10 grams

- Intuitive SPS control via touch screen

MDM

- Compact dosing system for fluid components

- Output ranges can be specified within 0.05 to 3.5 l/min

- Simple Siemens LOGO control

NODOPUR

- modular dosing system for flowing components

- Output ranges specifiable within 0.1 to 100 l/min

- Intuitive PLC control via touch screen

Processing of Pasty Components

“Pasty” or “thixotropic” are all components that have a viscosity of more than 60,000 mPas at processing temperature. They are supplied in cylindrical manufacturer’s containers in a stable state and must be processed with follow-on plate systems.

The NODOPOX series is suitable or pasty polyurethanes, epoxy resins and silicones. The rotating dosing pumps are inserted into the containers via the follower plate and achieve a very precise maintenance of the mixing ratio as well as pulsation-free dosing.

NODOPOX

- Modular dosing system for pasty components

- Output ranges specifiable within 0.1 to 30 l/min

- Intuitive PLC control via touch screen

NODOPOX wind

- Adhesive processing system for wind industry

- Output ranges can be specified within 5 to 20 l/min

- Intuitive SPS control via touch screen

Processing of Pasty Components and Liquid Hardeners

If liquid (1 to 60,000 mPas) and pasty (from 60,000 mPas) materials meet, a dosing and mixing system from the TARDOSIL series is used. As soon as a component is paste-like at processing temperature, a follower plate is used. In the case of liquid components, the material is conveyed through pressure vessels to the rotating dosing pump. The rotary pumps achieve a very high accuracy in dosing and mixing ratio – even with different viscosities and mixing ratios.

TARDOSIL

- Modular mixing system for paste-like components with liquid hardeners

- Output ranges specifiable within 0.1 to 30 l/min

- Intuitive PLC control via touch screen

Material Processing under Vacuum

Air and humidity damage many materials or disrupt the application process when they enter the machine. Last but not least, air and moisture in the material affect the quality of the end product.

The T-EVAC degassing station for evacuating air from liquid media and vacuum drum filling with TAVA F for pasty media, removes the harmful air from material and containers, thus optimizing the production process, increasing work safety and delivering measurably better results in product quality.

Vakuum-Entgasung (T-EVAC)

- Degassing of liquids

- As module of a dosing system or stand-alone solution

- Improves manufacturing process and product quality

Vakuum-Abfüllung (TAVA F)

- Filling of pasty components under vacuum

- Bubble-free filling without air inclusions

- Maximum safety in process and operation

Mixing heads

To ensure perfect interaction and the best results, we design and produce our mixing heads ourselves within the TARTLER GROUP and develop our own dynamic plastic mixers matching perfectly to the material.

- no dead spaces

- compact design

- universally applicable

- constant development

- optimal interaction with our mixing systems

- NEW! With self-tapping mixer connection

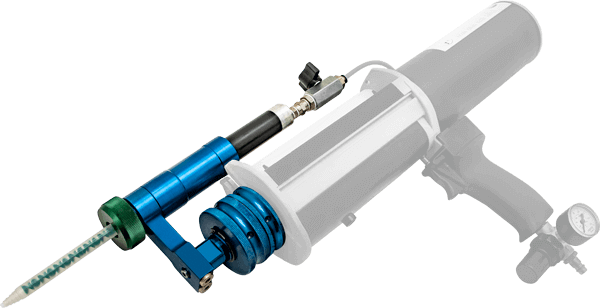

2K Cartridge Mixer LC-DCM

The first dynamic mixing for different cartridge systems

Universal cartridge gun attachment for precise dynamic mixing with reusable adapters for many common cartridge systems

Accessories

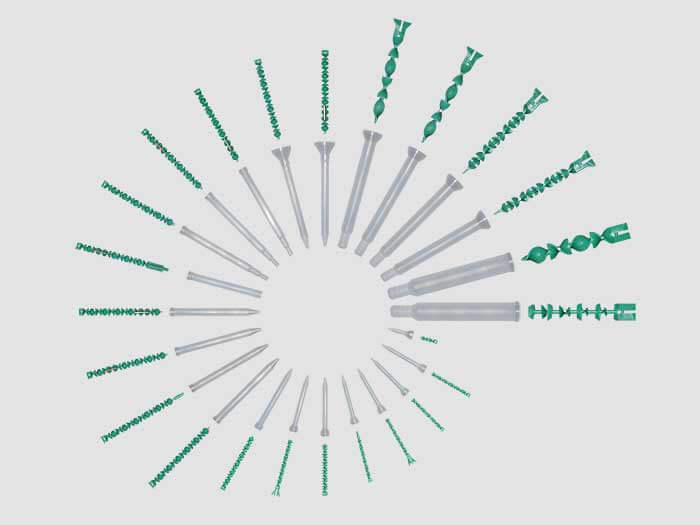

Mixer assortment

We have developed our extensive range of the patented rotating disposable plastic mixer in house. The perfect mixing of highly viscous, filled materials with low viscous, liquid components or extreme mixing ratios (100:2, 100:10) are the challenges to be faced.

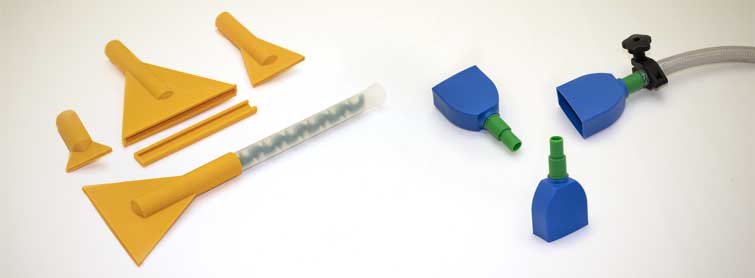

Consumables

Consumable parts developed for our machines in the usual TARTLER quality:

- Application nozzles for pastes in various designs

- Flat nozzles in different widths and with freely adjustable outlet for application of liquid synthetic resins

- CNC application nozzle for pastes for partially or fully automated application of pasty plastics

- Flowstop – self-sealing mould connection

- Hose clamps for safe connection between mixer and hose

- Centrifugal disc in different diameters for rotary discharge of material e.g. in pipes, components, tunnels

Always up-to-date with the TARTLER News!