The TARDOSIL series is required when pasty and liquid components need to be mixed homogeneously. With our patented dynamic disposable plastic mixers, we succeed in achieving optimum mixing regardless of enormous differences in viscosity and/or an extreme mixing ratio.

The systems can be designed as mobile or stationary versions. The number of components (2 components or more), as well as the program functions and other features from our module range, depend on the requirements of your specific production process.

With the buffer containers developed by us, which can be filled automatically from refill stations, you avoid process interruptions caused by drum changes during a dosing process. The refilling of liquid components can be done manually or automatically from various containers.

In order to improve or even guarantee process safety and operating safety for the user, we recommend selecting a module from our vacuum options.

Information about possible components and configurations can be obtained from our sales team.

Basic equipment

- Suitable for pasty resins with liquid hardeners made of silicone, polyurethane or epoxy

- Flow rates can be specified within 0.1 to 30 l/min

- Adjustable mixing ratio (self-regulating on request)

- Static mixer or disposable rotary plastic mixer possible

- Stainless steel tank 3 to 200 l

- Control: from simple user interface to touch panel

- Different tube lengths

- Requires compressed air

- Power connection: 400 volts

- Stationary or mobile, powder-coated steel frame (free choice of color) with integrated drip tray

Technical data

| Components | 2K or more components |

| Viscosity range | A: > 60.000 mPas B: 1 – 60.000 mPas |

| Mixing ratio | Adjustable mixing ratio (self-regulating on request) |

| Flow rate | Can be specified in the range from 0.1 to 30 l/min |

| Control system | From simple user interface to touch panel |

| Container | A: 20 (hobbock), 50, 200 l B: 30 l, 60 l, 100 l or 200 l |

| Available modules |

|

Module elements

A dosing system of the TARDOSIL series can be equipped with the following modules. As a manufacturer of special machines we adapt all machines to the respective process conditions.

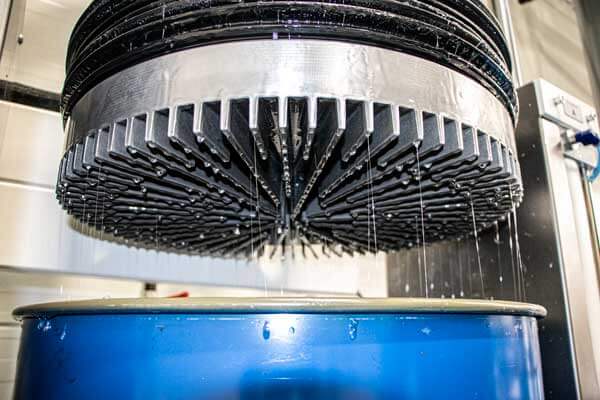

Air and humidity in the material reduce the material quality as well as the process stability. If the material is freed from this disturbing air before processing with a TAVA F, you create the best conditions for the actual application.

In addition to material optimization, the TAVA F module can also be used to reduce material costs and significantly improve the eco-balance of processing operations. Since unmixed material residues from opened drums, from trial runs, or from the setup phase no longer have to be rejected and disposed of thanks to the degassing station, but can be reused.

- Filling without any air pockets

- Improved storage stability

- Maximum occupational safety

- Guaranteed process reliability for subsequent applications

- Cost reduction through material preparation

| Categories : |

pastöse Komponenten

|

|---|

In order to be able to process non-flowable material at room temperature, it is often necessary to heat the tank and hoses. In order to protect sensitive material, a melting unit of the follower plate can melt / liquefy exactly as much material as is actually processed. The remaining material in the drum is not unnecessarily affected, as would happen if the tank were completely heated. In addition, time is saved because production can be started faster.

In order for the system to function, all other components, such as hoses and mixing head, must be equipped with a heater to prevent cold spots and thus guarantee optimum mixing of the components.

This melting unit is interesting for applications such as

- hot-cast adhesive

- hotmelt

| Categories : |

pastöse Komponenten

|

|---|

Zwischen Materialoberfläche und Folgeplatte wird ein Vakuum hergestellt. Die Folgeplatte wird erst nach Erreichen des definierten Vakuums – unter Einhaltung des Vakuums – kontrolliert abgesenkt. Somit die absolute Sicherheit, dass KEINE Luft in den Prozess gelangt!

Dieses System sorgt für einen absolut prozesssicheren Fasswechsel bei Folgeplattenanlagen für hochviskose Komponenten. Zusätzlich erreichen wir eine Steigerung der Arbeitssicherheit, es gibt weder Materialverlust noch besteht Spritzgefahr.

Eine Übersicht zu den Fasswechsel-Systemen finden Sie hier:

| Categories : |

pastöse Komponenten

|

|---|

Vacuum-assisted follower plate deaeration not only increases process and work safety but also reduces material loss.

The follower plate is lowered by extracting the air between the material surface and the follower plate until it sits tightly on the material. This drum change procedure is operator-friendly, prevents dangerous splashing and minimizes material loss, as no material has to be extracted via ball valve or similar outlet.

The machine operator can be sure that there is no harmful air, which would hinder the pumping process, between the follower plate and the material surface. The air is extracted at the push of a button. No manual intervention is required.

You can find more information on the subject of “drum change” here:

| Categories : |

pastöse Komponenten

|

|---|

- Quality-impairing air and humidity are removed from the resin

- Improved manufacturing process

- Enhanced product quality

Process-integrated evacuation of air and moisture from synthetic resins and hardeners before dosing and mixing with the T-EVAC degassing station.

With this module you can significantly improve your forming processes as well as your product quality. The new degassing station is suitable for both epoxy resin and polyurethane resin degassing.

The system solution is designed in two variants: First, as an offline degassing at a central location where several dosing units can be filled with degassed material. Second, as an inline degassing directly integrated into the dosing system and adapted to the process requirements.

Measurably better results with degassed material

Material test: Optimal result with degassed resin and hardener

Test result without degassing: visible air inclusions (light discoloration)

| Categories : |

Liquid components

|

|---|

All machine parts, from the container to the hose and mixing head, can be heated to reduce the viscosity of the material – for example, to shorten the pot life or improve mixing of the components. Depending on the application, there are several options available.

Container

- Jacket heating (adapted to the container)

- Double jacket (heating with water or oil)

- Extra agitators for a better heat distribution

Hoses

- Heated hoses

- Insulation

Depending on the sensitivity of the material, all possible cold spots must be additionally heated or insulated. Heating cartridges, ring heaters and heating tarpaulins are used in this process.

| Categories : |

Liquid components, pastöse Komponenten

|

|---|

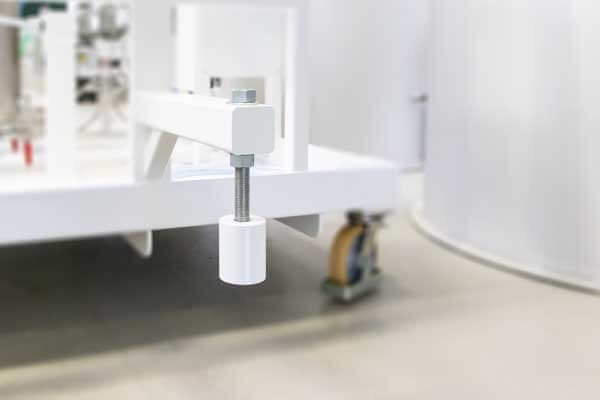

It may be necessary for a plant to be mobile, depending on its size and location/purpose. There are several ways to achieve mobility:

- Mobile frame

- Own drive unit

- Trailer coupling

| Categories : |

Liquid components, pastöse Komponenten

|

|---|

Machines with a volume flow control system continuously measure the flow rate of the material and report any deviations to the pumps, which automatically adjust the flow rate accordingly. This happens within seconds and guarantees a constant flow rate and mixing ratio.

| Categories : |

Liquid components, pastöse Komponenten

|

|---|

To keep the dosing process running longer, we offer refills from IBCs or drums. There are different solutions for the realization of a refill.

Automatic Refill

- 1st option: Dosing containers are connected to a mobile refilling station (modern connection with couplings without loss of material)

- 2nd option: Dosing containers are connected directly on the base frame with e.g. an IBC

- 3rd option: Refill containers are also located on the base frame

The process is controlled via automatic refilling e.g. when a minimum sensor level is reached.

Vacuum Refill

If the material must not come into contact with air, we offer dosing containers in vacuum atmosphere. When refilling, the negative pressure is used to “pull” the material out of the refill containers.

Free Refill

The free refill, also called “free-flow”, uses gravimetry. The material flows from the higher positioned refill container into the dosing containers. No pump is required.

| Categories : |

Liquid components, pastöse Komponenten

|

|---|

Sample projects / already built systems

Data sheet

Download more information about the TARDOSIL series here.

The right machine for your needs – we are happy to support you!

We would like to provide you with the best possible advice and require important information on your perfect metering and mixing system for the initial contact. Use our inquiry form – quick, easy, uncomplicated.

We are happy to advise you!

Markus Fesel

Technical sales & project management

Phone: +49 (0)6061 9672-13

m.fesel@tartler.com

We are happy to advise you!

Markus Fesel

Technischer Vertrieb & Projektmanagement

Phone: +49 (0)6061 9672-13

m.fesel@tartler.com

Always up-to-date with the TARTLER News!