The TARTLER accessories range offers many clever products for processing synthetic resin

When processing liquid and pasty synthetic resins, it is often intelligent detail solutions that determine the efficiency and productivity of an application. In addition to its range of dosing and mixing systems, TARTLER therefore offers its customers a wide selection of task-specific accessories and disposable elements. They simplify handling during application, improve mixing quality, reduce material waste and offer plenty of potential for all kinds of process optimization.

For many years, the ingenuity of TARTLER engineers has enriched resin processing in many industries. This is reflected not only in major innovations in the field of dosing, mixing and filling systems, but also in a growing range of accessories and disposables. The core of its product range remains the now very finely graduated range of dynamic disposable mixers for processing high and low viscosity, filled and liquid materials. However, TARTLER also offers a wide range of attachments, adapters including safety and connecting elements for special tasks and processes in synthetic resin technology. The selection here ranges from various paste nozzles and various cartridge adapters to metal safety pipes for mixers, and mould connections for resin transfer moulding (RTM) and resin casting. Some of these disposable parts were developed as customer-specific solutions for project activities, others were launched as independent product lines.

Mixers and nozzles for all applications

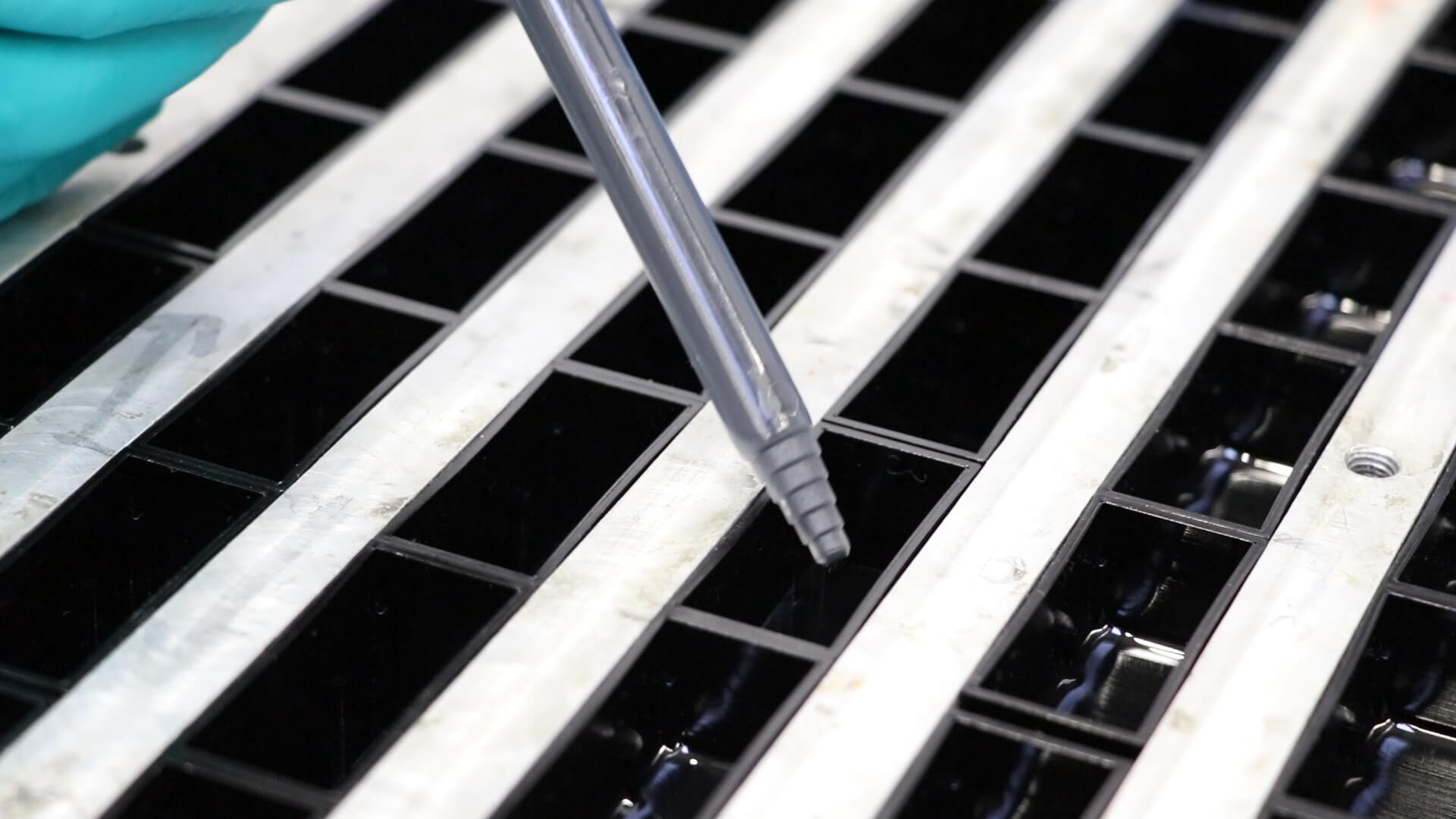

All TARTLER accessories have in common that they either simplify handling during application, improve the quality of the mixture, reduce waste or facilitate the implementation of process optimizations. Thanks to the special stability of their core, TARTLER’s disposable mixers, for example, not only allow higher torsional forces to be absorbed than is usually the case, but also allow optimum adaptation to almost any dosing and mixing task thanks to their different spiral geometries. What’s more, these mixers – always consisting of core and sleeve – are available both for conventional hook connections and for the patented self-cutting threaded connection.

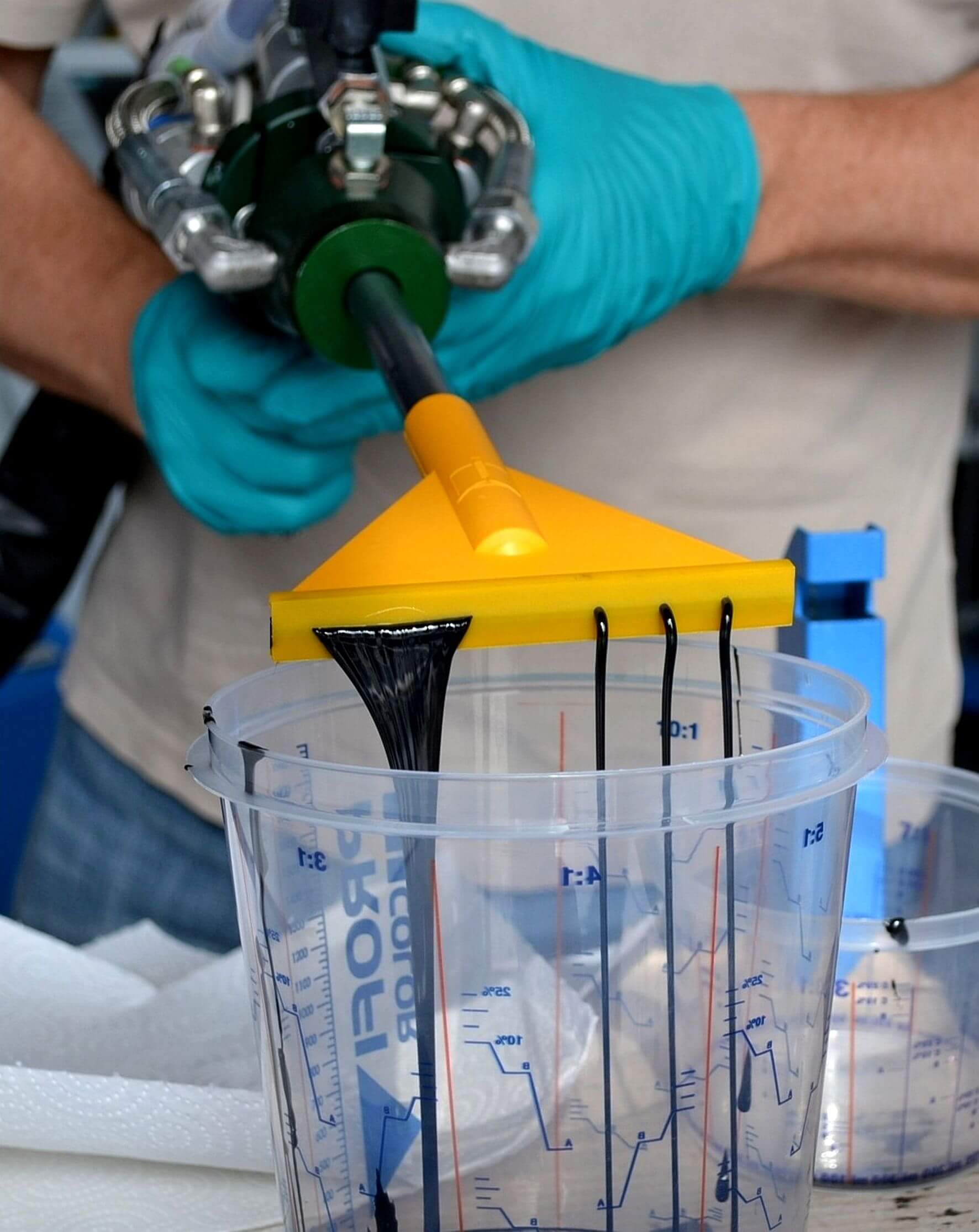

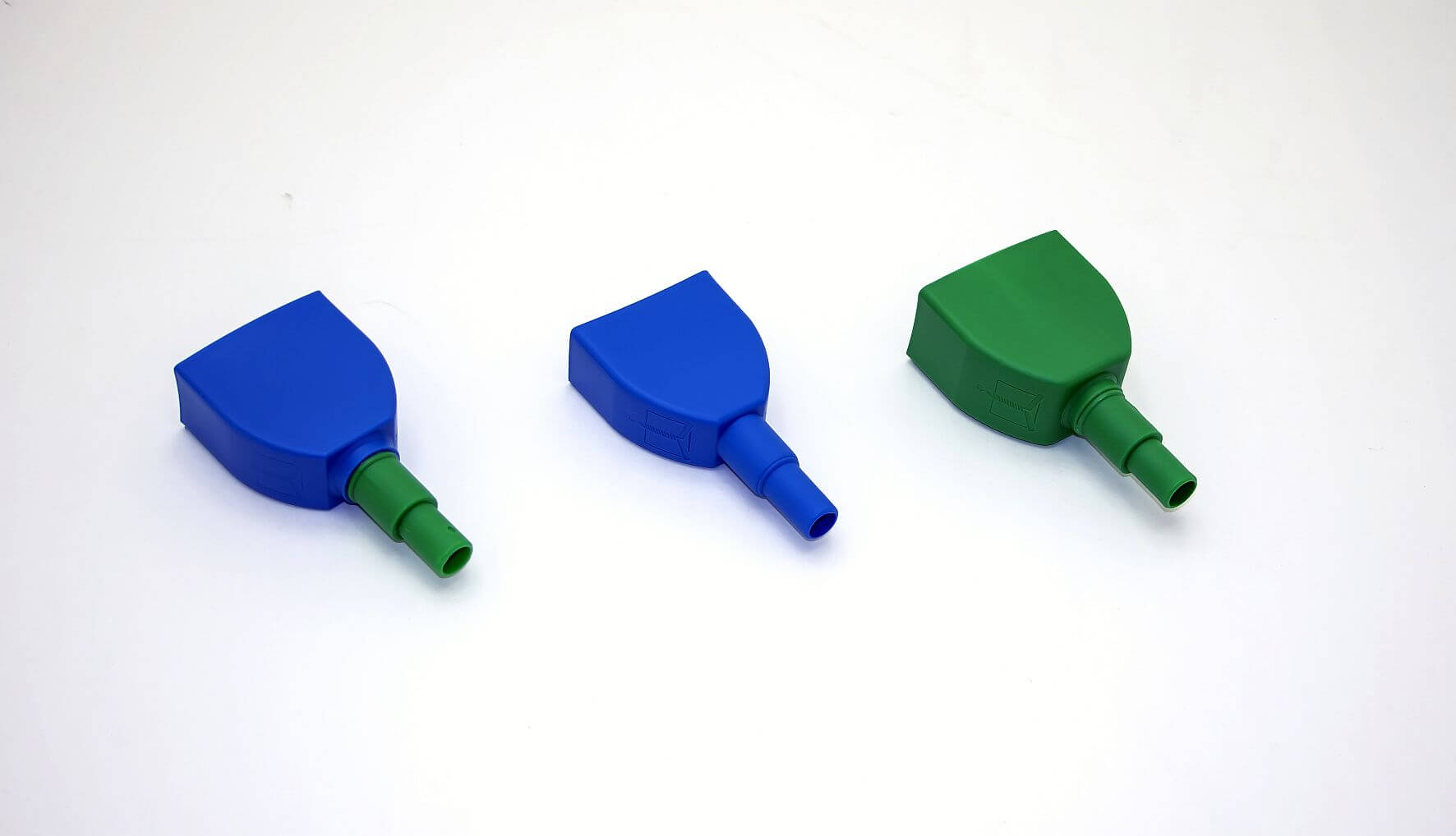

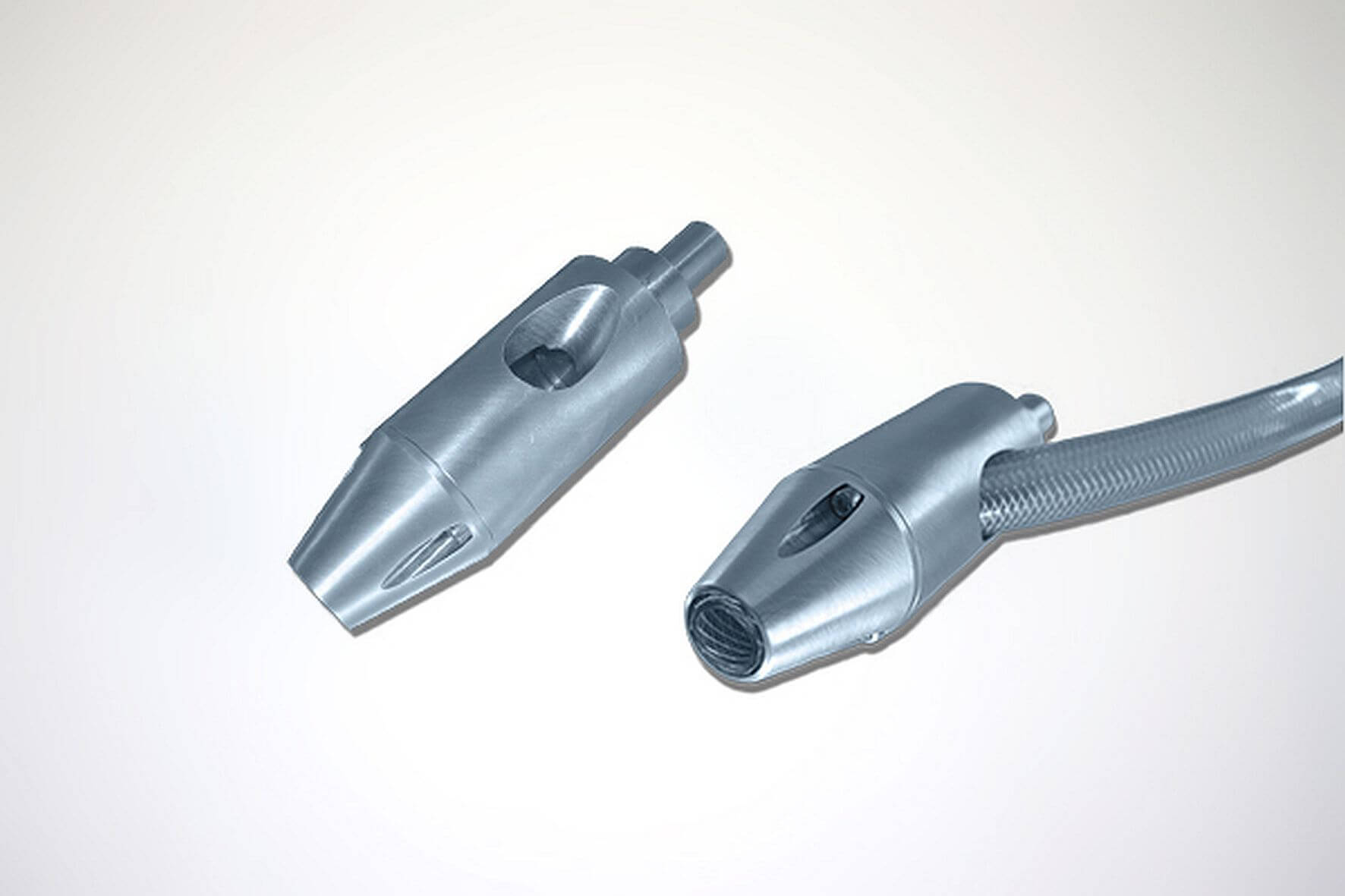

For users who work with highly viscous pastes, TARTLER offers a versatile selection of application nozzles made of plastic or stainless steel. Depending on the version, they have different outlet openings, fixed or rotating hose connections or are designed for automated CNC application. On the other hand, if you want to apply liquid synthetic resins in thin layers in web form, you will find a selection of special flat nozzles in the TARTLER accessories range. For applications that require rotary material discharge, the company offers centrifugal discs that are precisely designed for this task. They are used, among other things, for lining pipes and hollow body components.

Sealing, connecting and distributing

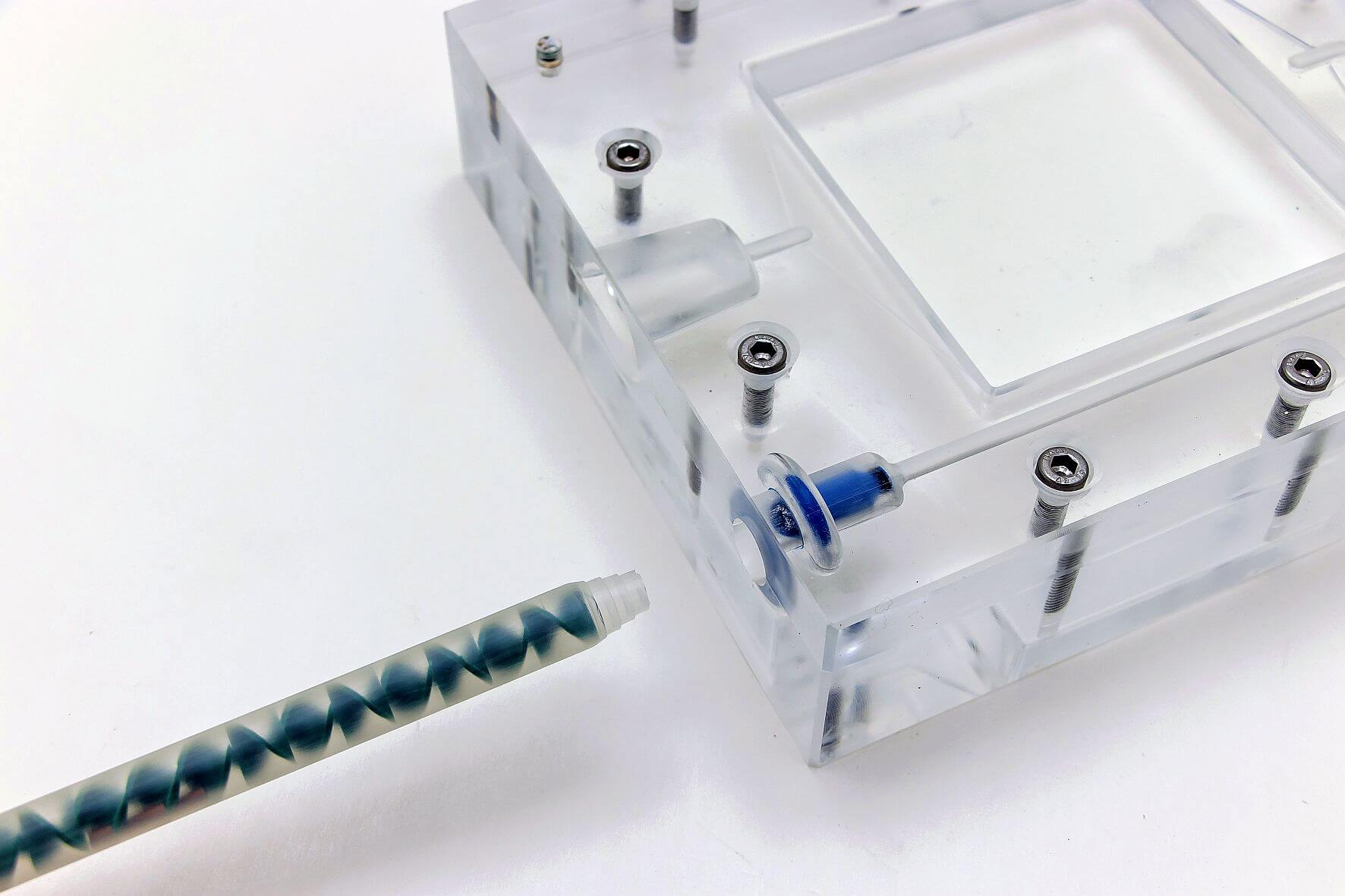

TARTLER’s Flowstop has established itself as an extremely successful innovation for resin moulding and the RTM (Resin Transfer Moulding) process. This is because this self-sealing plug prevents the media from flowing back when filling the mould. It is designed in such a way that it closes automatically after the injection of the synthetic resin mixture and seals the mould so that its internal pressure remains stable. The disposable part is available as standard for pressures from 0 to 30 bar; it is simply inserted into the mould. Further innovative accessories typical for TARTLER are the lockable hose clamp for the safe connection of mixers and hoses as well as the Y-connector with which media flows can be combined and divided.

Wide range of adapters

For users who primarily process small quantities of synthetic resin manually with standard pneumatic dispensers and use the new cartridge mixer attachment LC-DCM from TARTLER, the company has a large number of suitable adapters available in its accessories portfolio. This allows the LC-DCM to be coupled with Sulzer’s F and C systems or Nordson EFD’s Side x Side system in no time at all. The TARTLER cartridge attachment enables dynamic 2K mixing and allows small-quantity users to benefit from the quality advantages of dynamic dosing and mixing systems used in industrial large-scale applications.

Speaking of industrial synthetic resin processing: for the large multi-component mixing heads mainly used here, TARTLER’s range of accessories includes high-quality metal safety pipes (for mixers with and without speed sensing) as well as various test attachments and an easy-to-clean mixer connection with a smooth surface.

Lubricants (Tarmoll grease) for pumps and mixing heads as well as temperature-resistant PVC pressure hoses with different diameters complete the current TARTLER selection of disposables and accessories. However, anyone who has followed the Hessian company’s activities so far will know that its range of clever solutions will continue to grow in the coming months.