The LV 2/2 dosing mixing head from TARTLER simplifies the application of minimum quantities

In many areas of assembly technology, the dosing of minimal quantities and the application of very small quantities of multi-component plastics are critical stages of the gluing and sealing processes. In view of the advancing miniaturization of electrical-electronic assemblies and the associated development of micro-productions, they often take center stage in production. TARTLER offers the extremely flexible LV 2/2 dosing mixing head especially for this area of application. It is designed for the rapid production and application of low-viscosity mixtures in tiny shots of 1.0 to 10 grams. A technical highlight is its integrated load cell.

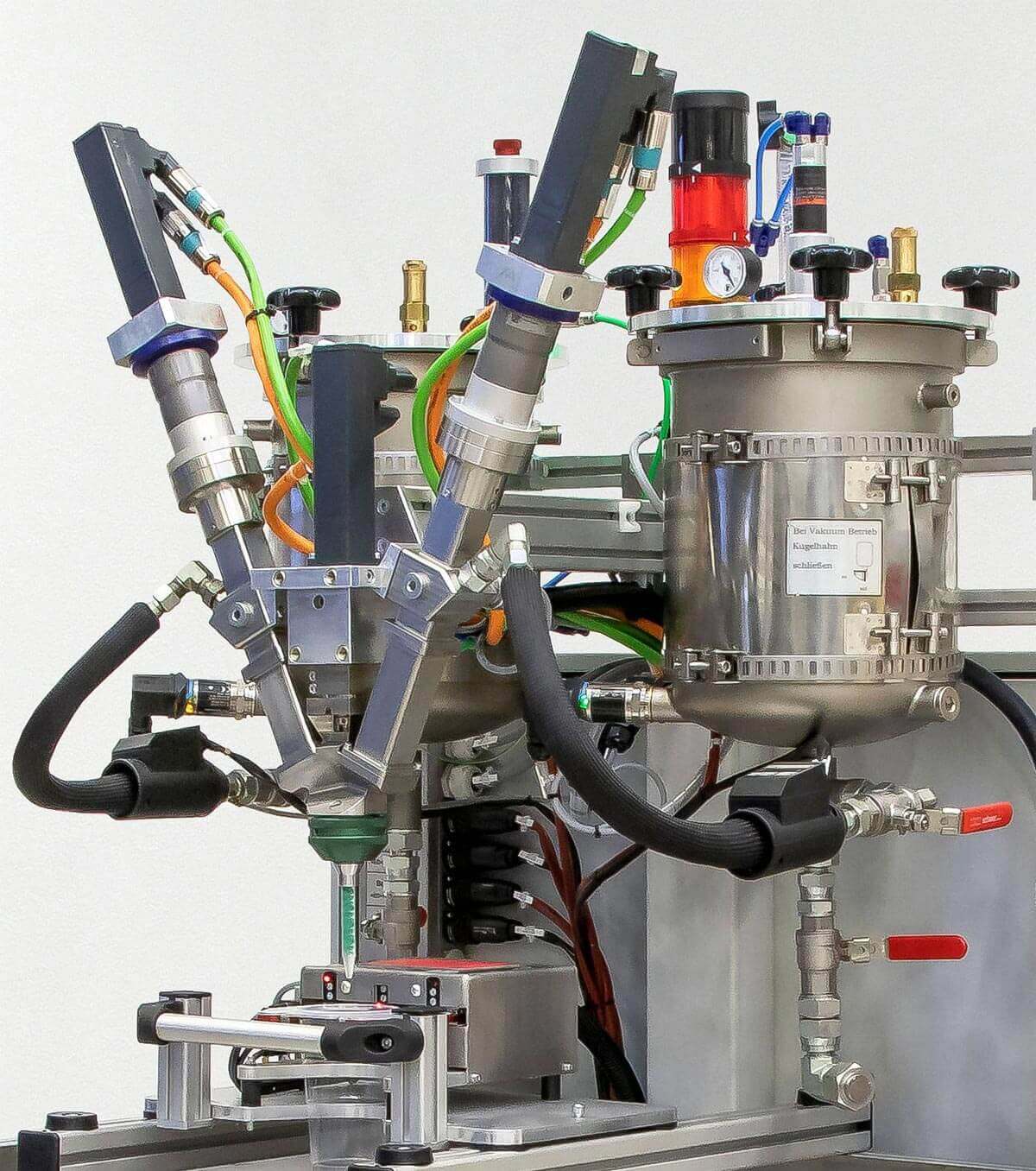

The LV 2/2 dosing mixing head from TARTLER is specially designed for dosing minimum quantities as well as the application of very small quantities of multi-component plastics. It is suitable for the production and application of low-viscosity mixtures in shot quantities of 1.0 to 10 grams.

The LV 2/2, one of the latest mixing head innovations from plant manufacturer TARTLER, is already used in many electrical engineering and electronics production lines. Here it serves as a system component for accurate dosing and mixing of low-viscosity, self-flowing synthetic resins (silicone, polyurethane, epoxy) and their precise and repeatable application in shot quantities of 1.0 to 10 grams. In this function, it has proven itself in the sealing of microelectronic components or in gluing tiny magnets into the rotors of compact e-mobility drives, for example. It is factory-set for the continuous processing of resins and hardeners with viscosities from 50 to 20,000 mPas in proportional mixing ratios from 100:5 to 100:200. However, as TARTLER’s Engineering has demonstrated, the LV 2/2 dosing mixing head can also be flexibly configured to many other mixing ratios, depending on the specific requirement. With an output that can be adjusted from 5.0 to 100 ml/min, the unit covers a wide range of applications.

Built-in Quality Assurance

One of the particular strengths of the LV 2/2 from TARTLER is its system-specific measurement module. This distinguishes it significantly from many other small-volume dosing systems on the market and not only greatly simplifies the process for the user, but also makes an important contribution to quality assurance. The integrated load cell of the LV 2/2 monitors both the mixing ratio and the shot weight during application, and automatically calibrates itself when used together with the Siemens controller and special software. This proprietary, self-calibrating load cell is an innovation in mixing head development. It improves process reliability, reduces non-productive times and increases efficiency when dosing small quantities and dosing of synthetic resins.

Designed for Dynamic Mixing

In order to enjoy these benefits, you need a compressed air connection and 400 volts to feed the energy-efficient servo drives of the pumps and the dosing mixing head. As usual with TARTLER, it is also possible to operate the LV 2/2 with the driven, rotating plastic mixing spirals offered by the company. With these dynamic disposable mixers, high-quality and homogeneous mixtures can be achieved even with extreme component recipes. The particularly short and slim type 06/04 D mixer from TARTLER, for example, is ideally suited for use in small-volume processing.

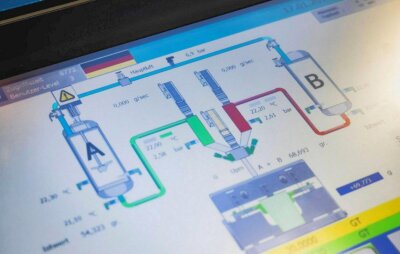

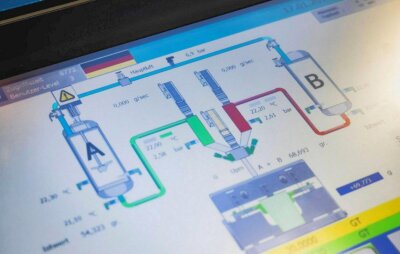

The LV2/2 from TARTLER is operated very conveniently via a four-color touch panel.

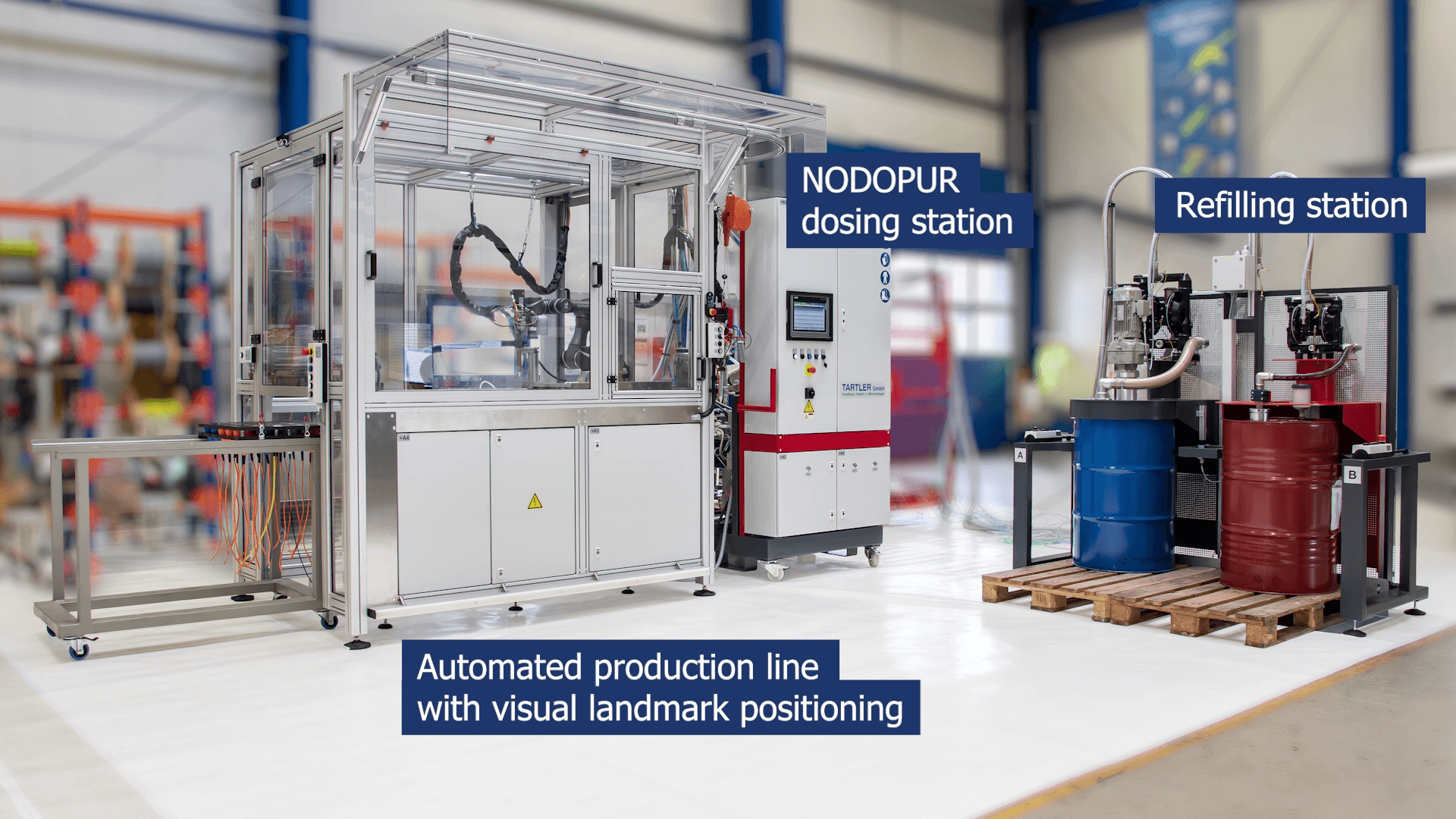

The LV2/2 is operated very conveniently via a four-color touch panel. The dosing/mixing head is supplied as standard with stainless steel containers that have a capacity of 3.0 to 200 liters. In addition, TARTLER offers a selection of additional modules that enable further process optimization in small-volume applications. For example, the LV 2/2 has heating, a refill unit, material degassing and a module for process logging and documentation. The innovative small-volume dosing mixing head is also available to customers as a portable unit with mobile substructure.

Expandable for 4K Applications

In the basic version, the LV 2/2 is available for processing up to two material components; however, it can also be upgraded at any time for dosing, mixing and applying up to four components. TARTLER offers all synthetic resin processors who have to apply tiny amounts of liquid synthetics, sealants and adhesives in the production line or laboratory a flexible and intelligent system solution that can be expanded with growing requirements. The operation of TARTLER’s innovative LV 2/2 dosing mixing head can be viewed in a dedicated product video.